Last Updated on June 6, 2023 by Eng Katepa

Cement, one of the most important building materials, is a binding agent that sets and hardens to adhere to building units such as stones, bricks, tiles, etc.

Cement generally refers to a very fine powdery substance chiefly made up of limestone (calcium), sand or clay (silicon), bauxite (aluminum), and iron ore, and may include shells, chalk, marl, shale, clay, blast furnace slag, slate.

The raw ingredients are processed in cement manufacturing plants and heated to form a rock-hard substance, which is then ground into a fine powder to be sold.

Cement mixed with water causes a chemical reaction and forms a paste that sets and hardens to bind individual structures of building materials.

Cement is an integral part of the urban infrastructure. It is used to make concrete and mortar, and to secure the infrastructure by binding the building blocks. Concrete is made of cement, water, sand, and gravel mixed in definite proportions, whereas mortar consists of cement, water, and lime aggregate.

These are both used to bind rocks, stones, bricks, and other building units, fill or seal any gaps, and make decorative patterns. Cement mixed with water silicates and aluminates makes a water-repellant hardened mass that is used for water-proofing.

Also Read: 16 Different Types of Concrete You Should Know Right Now

History of Cement

Cement, though different from the refined product found nowadays, has been used in many forms since the advent of human civilization.

From volcanic ashes, crushed pottery, burnt gypsum, and hydrated lime to the first hydraulic cement used by the Romans in the middle ages, the development of cement continued to the 18th century, when James Parker patented Roman cement, which gained popularity but was replaced by Portland cement in the 1850s.

In the 19th century, Frenchman Louis Vicat laid the foundation for the chemical composition of Portland cement and in Russia, Egor Cheliev published the methods of making cement, uses of cement, and advantages.

Joseph Aspdin brought Portland cement to the market in England and his son, William Aspdin, developed the “modern” Portland cement, which was soon in quite high demand.

But the real father of Portland cement is considered to be Isaac Charles Johnson, who contributed immensely by publishing the process of developing meso-Portland cement in the kiln.

In the 19th century, Rosendale cement was discovered in New York. Though its rigidity made it quite famous at first, the market demand soon declined because of its long curing time and Portland cement was again the favorite. However, a new blend of Rosendale-Portland cement, which is both highly durable and needs less curing time, was synthesized by Catskill Aqueduct and is now often used for highway or bridge construction.

The cement used today has undergone experimentation, testing and significant improvements to meet the needs of the present world, such as developing strong concretes for roads and highways, hydraulic mortars that endure sea water, and stucco for wet climates.

Different kinds of modern cement, most of them known as Portland cement or blends, include blast furnace cement, Portland fly-ash cement, Portland pozzolan cement, pozzolan-lime cement, slag-lime cement, etc.

Cement Chemistry

Cement is chiefly of two kinds based on the way it is set and hardened: hydraulic cement, which hardens due to the addition of water, and non-hydraulic cement, which is hardened by carbonation with the carbon present in the air, so it cannot be used underwater.

Non-hydraulic cement is produced through the following steps (lime cycle):

- Calcination: Lime is produced from limestone at over 825°C for about 10 hours. (CaCO3 → CaO + CO2)

- Slaking: Calcium oxide is mixed with water to make slaked lime. (CaO + H2O → Ca(OH)2)

- Setting: Water is completely evaporated.

- The cement is exposed to dry air and it hardens after time-consuming reactions. (Ca(OH)2 + CO2 → CaCO3 + H2O)

On the other hand, hydraulic cement is mainly made up of silicates and oxides:

- Belite (2CaO·SiO2);

- Alite (3CaO·SiO2);

- Tricalcium aluminate/ Celite (3CaO·Al2O3)

- Brownmillerite (4CaO·Al2O3·Fe2O3)

The ingredients are processed in the kiln in cement plants. The complete chemistry of the reactions is still a subject of research.

Portland cement

The most commonly used cement nowadays is hydraulic cement (i.e. hardens when water is added) known as Portland cement or Portland cement blends. These are usually the basic ingredient in making concrete, which is a construction material used as a load-bearing element. Portland cement is suitable for wet climates and can be used underwater.

Different types or blends of Portland cement include Portland blast furnace slag cement, Portland fly-ash cement, Portland pozzolan cement, Portland-silica fume cement, masonry cement, expansive cement, white blended, colored cement, and very finely ground cement.

Composition of Portland cement

85% Portland cement clinker (37-72% of 3CaO.SiO2; 6-47% 2CaO.SiO2; 2-20% 2CaO.Al2O3; 2-19% 4CaO. Al2O3.Fe2O3), 1.5-3.5% gypsum by SO3 content, up to 15% admixtures.

How to make Portland cement

In a cement production plant, limestone and other raw materials such as silicate, bauxite, iron ore, etc. are heated so that molecules of carbon dioxide are liberated from the limestone to form quicklime, which combines with the other ingredients, resulting in the formation of calcium silicates and other products.

Thus clinker, a rock-hard substance, is made. Gypsum is added to the clinker and then ground into a fine powder, which is the final product known as Portland cement.

Cement Manufacturing Industries in the World

The top three cement producers in the world as recorded in 2020 are the USA, China, and India. Among these countries, China alone manufactures about 45% of the total worldwide production of cement.

Global consumption of cement continues to rise since it is a non-recyclable product and so every new construction or repair needs new cement. Especially in the economies of Asia and Eastern Europe, cement production is an important element of progress.

According to the global cement directory, there are about 2273 active cement production plants in the world. Some of the leading cement manufacturers are LafargeHolcim, Anhui Conch, China National Building Materials, HeidelbergCement, Cemex, Italcementi, China Resources Cement, Taiwan Cement, Eurocement, and Votorantim.

The total global consumption of cement, as indicated by statistics in 2015, measures up to 18 million metric tons, most of which is attributed to the rising national economy of North America.

Among the developed capitalist countries, the leading producers of cement are the USA, France, Italy, and Germany. Iran, now the top producer in the Middle East, occupies the third position in the world for cement manufacture. Asian and African countries are also progressive in the production of cement.

The kiln process in cement plants causes the emission of carbon dioxide, which is one of the major greenhouse gases responsible for global warming.

With a view to reducing, even eliminating, the harmful environmental impacts of cement usage, leading industries are now trying to implement technologies that utilize recycled materials and renewable energy sources. “Green cement” is such a sustainable construction material that is the result of extensive research related to the check the effects of global warming.

Also Read: Floor and Decor: Types and Materials In 2023

Types of cement

Cement is mainly classified into two categories depending on the hardening and setting mechanism. These are-

- Hydraulic Cement

- Non-hydraulic Cement

Along with these main types, depending on the composition and characteristics there are many types of cement. The followings are the other cement types:

- Ordinary Portland Cement (OPC)

- Portland Pozzolana Cement (PPC)

- Rapid Hardening Cement

- Quick Setting Cement

- Low Heat Cement

- Sulphate Resisting Cement

- Blast Furnace Cement

- High Alumina Cement

- White Cement

- Colored Cement

- Air Entraining Cement

- Expansive Cement

- Hydrophobic Cement

Brief descriptions of these cement types with their uses are given below.

Hydraulic Cement

As the name indicates, hydraulic cement is one that hardens by hydration in the presence of water. Limestone, clay, and gypsum are the main raw material to produce non-hydraulic cement. This raw material is burned at a very high temperature to manufacture Hydraulic Cement.

Hydraulic cement (cement that not only hardens by reacting with water but also forms a water-resistant product) produced by pulverizing clinkers which consist essentially of hydraulic calcium silicates, usually containing one or more of the forms of calcium sulfate as an inter ground addition.ASTM C150

Non-Hydraulic Cement

The non-hydraulic cement doesn’t require water to get harden. It gets with the help of carbon dioxide (CO2) from the air. This type of cement needs dry conditions to harden. Lime, gypsum plasters, and oxychloride are the required raw material to produce non-hydraulic cement. Example: slaked lime is a non-hydraulic cement.

Ordinary Portland Cement (OPC)

In usual construction work, Ordinary Portland Cement is widely used.

Portland cement clinker is a hydraulic material which shall consist of at least two-thirds by mass of calcium silicates, (3 CaO·SiO2, and 2 CaO·SiO2), the remainder consisting of aluminium- and iron-containing clinker phases and other compounds. The ratio of CaO to SiO2 shall not be less than 2.0. The magnesium oxide content (MgO) shall not exceed 5.0% by mass.European Standard EN 197-1

The composition of Ordinary Portland Cement:

- Argillaceous or silicates of alumina (clay and shale)

- Calcareous or calcium carbonate (limestone, chalk, and marl)

Uses of Ordinary Portland Cement

- It is used for general construction purposes.

- It is also used in most masonry works.

Portland Pozzolana Cement (PPC)

Pozzolans are natural or synthetic materials that contain silica in reactive forms. It reacts with calcium hydroxide generated by hydrating cement to form additional cementation materials when it is finely divided. The composition of Portland Pozzolana Cement:

- OPC clinker

- Gypsum

- Pozzolanic Materials (Fly ash, volcanic ash, and Calcined clay or silica fumes.)

Uses of Portland Pozzolana Cement

- PPC is usually used in hydraulic structures, marine structures, construction near the seashore, dam construction, etc.

- It is also used in pre-stressed and post-tensioned concrete members.

- As it gives a better surface finish, it is used in decorative and art structures.

- It is also used in the manufacture of precast sewage pipes.

Rapid Hardening Cement

When finely grounded Tri-calcium silicate (C3S) is present in OPC with higher content, it gains strength more quickly than OPC. This type of OPC is called Rapid Hardening Cement. Its initial Setting Time is 30 minutes and its Final Setting Time is 600 minutes.

Uses of Rapid Hardening Cement

- Rapid hardening cement is mostly used where rapid construction is needed like the construction of pavement.

- It also gives high strength.

Quick Setting Cement

Quick-setting cement is the cement that sets in a very short time. The initial setting time is 5 minutes and the final setting time is 30 minutes. The composition of Quick Setting Cement:

- Clinker

- Aluminum sulfate (1% to 3% by weight of clinker)

- The aluminum sulfate increases the hydration rate of silicate.

Uses of Quick Setting Cement

- It is used in underwater construction.

- It is also used in rainy & cold weather conditions.

- It is used at a higher temperature where water evaporates easily.

- Used for anchoring or rock bolt mining and tunneling

Low Heat Cement

It is a spatial type of cement that produces low heat of hydration during the setting. Some chemical composition of Ordinary Portland Cement is modified to reduce the heat of hydration. The chemical composition of low-heat cement:

- A low percentage (5%) of tricalcium aluminate (C3A)

- A higher percentage (46%) of declaiming silicate (C2S).

Uses of Low-Heat Cement

- It is used for the construction of a dam’s large footing, large raft slabs, and wind turbine plinths.

- It is also used for the construction of chemical plants.

Sulphate Resisting Cement

Sulfate-resisting cement is used to resist sulfate attacks in concrete. Due to the lower percentage of Tricalcium aluminate, the production of calcium sulpho-aluminates gets reduced.

Uses of Sulphates resisting Cement

- Construction in contact with soils or groundwater having more than 0.2% or 0.3 % g/l sulfate salts respectively.

- Concrete surfaces subjected to alternate wetting and drying such as bridge piers, concrete surface in the tidal zone, aprons, and buildings near the seacoast.

- Effluent treatment plans, chimneys, Chemical industries, water storage, sumps, drainage works, Cooling towers, Coastal protective works such as sea walls, breakwaters, tetrapods, etc.

Blast Furnace Cement

Portland cement clinker and granulated blast furnace slag are intergraded to make blast furnace cement. A maximum of 65 percent of the mixture could be comprised of blast furnace slag.

Uses of Blast Furnace Cement

- It is highly sulfate resistant

- Frequently used in seawater construction.

High Alumina Cement

High Alumina cement is obtained by mixing calcining bauxite (it’s an aluminum ore) and ordinary lime with clinker during the manufacture of OPC. In which the total amount of alumina content should not be lesser than 32% and it should maintain the ratio by weight of alumina to the lime between 0.85 to 1.30.

Uses of High Alumina Cement

- It is used where concrete structures are subjected to high temperatures like workshops, refractories, foundries, etc.

- It is also used where the concrete is subjected to frost and acidic action.

White Cement

White cement is quite similar to Ordinary Portland Cement except for color. Amounts of iron oxide and manganese oxide are low in White Cement. It is more expensive than OPC so not economical for ordinary work.

Uses of White Cement

- It is usually used in decorative work.

- It can also use for traffic barriers, tile grouts, swimming pools, roof tiles patching materials, and terrazzo surfaces.

Colored Cement

To make 5 to 10 percent of suitable pigments are ground with OPC. Types of pigments are selected according to the desired color.

Uses of Colored Cement

- Colored cement is used for different decorative work.

Air Entraining Cement

It is seen that the entrainment of air or the formation of gas bubbles while applying cement increases resistance to frost action, fire, scaling, and other similar defects. Air-entraining cement is a special type of cement that entrains tinny air bubbles in concrete.

It is produced by grinding minute air entertaining materials with clinker by adding some resinous materials e.g. vinyl resin to ordinary portland cement.

When the water in concrete gets frizzed due to low temperature, it expands. When air-entraining cement, the air voids in the concrete provide space for water to expand without cracking concrete. But this type of cement does not provide high strength in concrete.

Uses of Air-Entraining Cement

- Especially it is used in areas where the temperature is very low.

- It also resists the Sulphet attack.

- It is used where the de-icing chemical is used.

Expansive Cement

In the hydration process, the expansive cement expands its volume. It can be possible to overcome shrinkage loss by using expansive cement.

There are three types of expansive cement:

- K Type expansive cement

- M Type expansive cement

- S Type expansive cement

K Type expansive cement

Raw materials of these types of cement

- Portland cement

- Anhydrous tetra calcium trialuminate sulfate (C4A3S)

- Calcium sulfate (CaSO4)

- Lime (CaO).

M Type Expansive Cement

Raw materials of these types of cement

- Portland cement clinkers

- Calcium sulfate.

S Type Expansive Cement

Raw materials of these types of cement

- Portland cement clinkers

- Calcium sulfate (High amount)

- Tricalcium aluminate (C3A) (High amount)

Uses of Expansive cement

- It is used in the construction of the pre-stressed concrete component.

- It is also used for sealing joints and grouting anchor bolts.

- In the construction of different hydraulic structures, this type of cement is used.

Hydrophobic Cement

To resist the hydration process in the transportation or storage stage, clinkers are ground with water-repellent film substances such as Oleic Acid or Stearic Acid.

These chemicals form a layer on the cement particle and do not allow water to mix and start the hydration process. When cement and aggregate are thoroughly mixed in the mixer, protective layers break and start normal hydration with some air entrainment which increases workability.

Uses of Hydrophobic Cement

- Usually, it is used in the construction of water structures such as dams, spillways, or other submerged structures.

- It is also used in the construction of underground structures like tunnels etc.

Also Read: Types of Glasses for Construction You Need To Know In 2023

Main Cement Ingredients

The main features of these cement ingredients along with their functions and usefulness or harmfulness are given below:

- Lime: Lime is calcium oxide or calcium hydroxide.

- The presence of lime in a sufficient quantity is required to form silicates and aluminates of calcium.

- A deficiency in lime reduces the strength of the property to the cement.

- A lack of lime causes the cement to set quickly.

- Excess lime makes cement unsound.

- The excessive presence of lime causes the cement to expand and disintegrate.

- Silica: Silicon dioxide is known as silica, chemical formula SiO2.

- A sufficient quantity of silica should be present in cement to dicalcium and tricalcium silicate.

- Silica imparts strength to cement.

- Silica usually presents to the extent of about 30 percent cement.

- Alumina: Alumina is Aluminium oxide. The chemical formula is Al2O3.

- Alumina imparts quick setting property to the cement.

- Clinkering temperature is lowered by the presence of the requisite quantity of alumina.

- Excess alumina weakens the cement.

- Magnesia: Magnesium Oxide. The chemical formula is MgO.

- Magnesia should not be present more than 2% in cement.

- Excess magnesia will reduce the strength of the cement.

- Iron oxide: The chemical formula is Fe2O3.

- Iron oxide imparts color to cement.

- It acts as a flux.

- At a very high temperature, it imparts into the chemical reaction with calcium and aluminum to form tricalcium alumino-ferrite.

- Tricalcium alumino-ferrite imparts hardness and strength to cement.

- Calcium Sulfate: The chemical formula is CaSO4

- This is present in cement in the form of gypsum(CaSO4.2H2O)

- It slows down or retards the setting action of cement.

- Sulfur Trioxide: The chemical formula is SO3

- It should not be present for more than 2%.

- Excess Sulfur Trioxide causes the cement to unsound.

- Alkaline:

- It should not be present more than 1%.

- Excess Alkaline matter causes efflorescence.

Chemical Formulas of Cement Materials

Cement is made of different chemical components as discussed above. Cement chemical composition is dependent on the chemical composition of these ingredients. These components have their own chemical formula. There is no specific chemical formula for cement itself.

The followings are the chemical formula for the major components of a cement.

- Lime -Ca(OH)₂

- Silica – SiO2

- Alumina – Al2O3

- Magnesia – MgO

- Iron oxide – Fe2O3

- Calcium Sulfate – CaSO4

- Sulfur Trioxide – SO3

- Alkaline – “X”(OH) 2

Also Read: What is the Function of Buildings?

Properties of Cement

Physical Properties of Cement

Different blends of cement used in construction are characterized by their physical properties. Some key parameters control the quality of cement. The physical properties of good cement are based on:

- Fineness of cement

- Soundness

- Consistency

- Strength

- Setting time

- Heat of hydration

- Loss of ignition

- Bulk density

- Specific gravity (Relative density)

These physical properties are discussed in detail in the following segment. Also, you will find the test names associated with these physical properties.

Fineness of Cement

The size of the particles of the cement is its fineness. The required fineness of good cement is achieved through grinding the clinker in the last step of cement production process. As hydration rate of cement is directly related to the cement particle size, fineness of cement is very important.

Soundness of Cement

Soundness refers to the ability of the cement to not shrink upon hardening. Good quality cement retains its volume after setting without delayed expansion, which is caused by excessive free lime and magnesia.

Tests:

Unsoundness of cement may appear after several years, so tests for ensuring soundness must be able to determine that potential.

- Le Chatelier Test

This method, done by using Le Chatelier Apparatus, tests the expansion of cement due to lime. Cement paste (normal consistency) is taken between glass slides and submerged in water for 24 hours at 20+1°C. It is taken out to measure the distance between the indicators and then returned underwater, brought to a boil in 25-30 mins, and boiled for an hour. After cooling the device, the distance between indicator points is measured again. In good quality cement, the distance should not exceed 10 mm. - Autoclave Test

Cement paste (of normal consistency) is placed in an autoclave (high-pressure steam vessel) and slowly brought to 2.03 MPa, and then kept there for 3 hours. The change in length of the specimen (after gradually bringing the autoclave to room temperature and pressure) is measured and expressed in percentage. The requirement for good quality cement is a maximum of 0.80% autoclave expansion.

Standard autoclave test: AASHTO T 107 and ASTM C 151: Autoclave Expansion of Portland Cement.

Consistency of Cement

The ability of cement paste to flow is consistent.

It is measured by Vicat Test.

In the Vicat Test Cement paste of normal consistency is taken in the Vicat Apparatus. The plunger of the apparatus is brought down to touch the top surface of the cement. The plunger will penetrate the cement up to a certain depth depending on the consistency. A cement is said to have a normal consistency when the plunger penetrates 10±1 mm.

Strength of Cement

Three types of strength of cement are measured – compressive, tensile, and flexural. Various factors affect the strength, such as water-cement ratio, cement-fine aggregate ratio, curing conditions, size and shape of a specimen, the manner of molding and mixing, loading conditions, and age. While testing the strength, the following should be considered:

- Cement mortar strength and cement concrete strength are not directly related. Cement strength is merely a quality control measure.

- The tests of strength are performed on cement mortar mix, not on cement paste.

- Cement gains strength over time, so the specific time of performing the test should be mentioned.

Compressive Strength

It is the most common strength test. A test specimen (50mm) is taken and subjected to a compressive load until failure. The loading sequence must be within 20 seconds and 80 seconds.

Standard tests:

- AASHTO T 106 and ASTM C 109: Compressive Strength of Hydraulic Cement Mortars (Using 50-mm or 2-in. Cube Specimens)

- ASTM C 349: Compressive Strength of Hydraulic Cement Mortars (Using Portions of Prisms Broken in Flexure)

Tensile strength

Though this test used to be common during the early years of cement production, now it does not offer any useful information about the properties of cement.

Flexural strength

This is actually a measure of tensile strength in bending. The test is performed in a 40 x40 x 160 mm cement mortar beam, which is loaded at its center point until failure.

Standard test:

- ASTM C 348: Flexural Strength of Hydraulic Cement Mortars.

Setting Time of Cement

Cement sets and hardens when water is added. This setting time can vary depending on multiple factors, such as the fineness of cement, cement-water ratio, chemical content, and admixtures. Cement used in construction should have an initial setting time that is not too low and a final setting time not too high. Hence, two setting times are measured:

- Initial set: When the paste begins to stiffen noticeably (typically occurs within 30-45 minutes)

- Final set: When the cement hardens, being able to sustain some load (occurs below 10 hours)

Again, setting time can also be an indicator of hydration rate.

Standard Tests:

- AASHTO T 131 and ASTM C 191: Time of Setting of Hydraulic Cement by Vicat Needle

- AASHTO T 154: Time of Setting of Hydraulic Cement by Gillmore Needles

- ASTM C 266: Time of Setting of Hydraulic-Cement Paste by Gillmore Needles

Heat of Hydration

When water is added to cement, the reaction that takes place is called hydration. Hydration generates heat, which can affect the quality of the cement and also be beneficial in maintaining curing temperature during cold weather. On the other hand, when heat generation is high, especially in large structures, it may cause undesired stress.

The heat of hydration is affected most by C3S and C3A present in cement, and also by water-cement ratio, fineness, and curing temperature. The heat of hydration of Portland cement is calculated by determining the difference between the dry and the partially hydrated cement (obtained by comparing these at the 7th and 28th days).

Standard Test:

ASTM C 186: Heat of Hydration of Hydraulic Cement

Loss of Ignition

Heating a cement sample at 900 – 1000°C (that is until a constant weight is obtained) causes weight loss. This loss of weight upon heating is calculated as loss of ignition. Improper and prolonged storage or adulteration during transport or transfer may lead to pre-hydration and carbonation, both of which might be indicated by the increased loss of ignition.

Standard Test:

AASHTO T 105 and ASTM C 114: Chemical Analysis of Hydraulic Cement

Bulk density

When cement is mixed with water, the water replaces areas where there would normally be air. Because of that, the bulk density of cement is not very important. Cement has a varying range of density depending on the cement composition percentage. The density of cement may be anywhere from 62 to 78 pounds per cubic foot.

Specific Gravity (Relative Density)

Specific gravity is generally used in mixture proportioning calculations. Portland cement has a specific gravity of 3.15, but other types of cement (for example, portland-blast-furnace-slag and portland-pozzolan cement) may have specific gravities of about 2.90.

Standard Test:

AASHTO T 133 and ASTM C 188: Density of Hydraulic Cement

Chemical Properties of Cement

The raw materials for cement production are limestone (calcium), sand or clay (silicon), bauxite (aluminum), and iron ore, and may include shells, chalk, marl, shale, clay, blast furnace slag, and slate. Chemical analysis of cement raw materials provides insight into the chemical properties of cement.

- Tricalcium aluminate (C3A)

The low content of C3A makes the cement sulfate resistant. Gypsum reduces the hydration of C3A, which liberates a lot of heat in the early stages of hydration. C3A does not provide any more than a little amount of strength.

Type I cement: contains up to 3.5% SO3 (in cement having more than 8% C3A)

Type II cement: contains up to 3% SO3 (in cement having less than 8% C3A) - Tricalcium silicate (C3S)

C3S causes rapid hydration as well as hardening and is responsible for the cement’s early strength gain in an initial setting. - Dicalcium silicate (C2S)

As opposed to tricalcium silicate, which helps early strength gain, dicalcium silicate in cement helps the strength gain after one week. - Ferrite (C4AF)

Ferrite is a fluxing agent. It reduces the melting temperature of the raw materials in the kiln from 3,000°F to 2,600°F. Though it hydrates rapidly, it does not contribute much to the strength of the cement. - Magnesia (MgO)

The manufacturing process of Portland cement uses magnesia as a raw material in dry process plants. An excess amount of magnesia may make the cement unsound and expansive, but a little amount of it can add strength to the cement. Production of MgO-based cement also causes less CO2 emission. All cement is limited to a content of 6% MgO. - Sulfur trioxide

Sulfur trioxide in excess amounts can make cement unsound. - Iron oxide/ Ferric oxide

Aside from adding strength and hardness, iron oxide or ferric oxide is mainly responsible for the color of the cement. - Alkalis

The amounts of potassium oxide (K2O) and sodium oxide (Na2O) determine the alkali content of the cement. Cement containing large amounts of alkali can cause some difficulty in regulating the setting time of cement. Low-alkali cement, when used with calcium chloride in concrete, can cause discoloration. In slag-lime cement, ground granulated blast furnace slag is not hydraulic on its own but is “activated” by the addition of alkalis. There is an optional limit in total alkali content of 0.60%, calculated by the equation Na2O + 0.658 K2O. - Free lime

Free lime, which is sometimes present in cement, may cause expansion. - Silica fumes

Silica fume is added to cement concrete in order to improve a variety of properties, especially compressive strength, abrasion resistance, and bond strength. Though setting time is prolonged by the addition of silica fume, it can grant exceptionally high strength. Hence, Portland cement containing 5-20% silica fume is usually produced for Portland cement projects that require high strength. - Alumina

Cement containing high alumina has the ability to withstand frigid temperatures since alumina is chemical-resistant. It also quickens the setting but weakens the cement.

Also Read: Types of Glasses for Construction You Need To Know In 2023

Manufacturing Process of Cement

There are six main stages of the cement manufacturing process.

Stage 1: Raw Material Extraction/Quarry

The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and crushed into smaller pieces of about 6 inches. Secondary crushers or hammer mills then reduce them to an even smaller size of 3 inches. After that, the ingredients are prepared for processing.

Stage 2: Grinding, Proportioning, and Blending

The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture.

The composition of cement is proportioned here depending on the desired properties of the cement. Generally, limestone is 80%, and the remaining 20% is clay. In the cement plant, the raw mix is dried (moisture content reduced to less than 1%); heavy wheel-type rollers and rotating tables blend the raw mix and then the roller crushes it to a fine powder to be stored in silos and fed to the kiln.

Stage 3: Pre-Heating Raw Material

A pre-heating chamber consists of a series of cyclones that utilizes the hot gases produced from the kiln in order to reduce energy consumption and make the cement-making process more environment-friendly. The raw materials are passed through here and turned into oxides to be burned in the kiln.

Stage 4: Kiln Phase

The kiln phase is the principal stage of the cement production process. Here, clinker is produced from the raw mix through a series of chemical reactions between calcium and silicon dioxide compounds. Though the process is complex, the events of the clinker production can be written in the following sequence:

- Evaporation of free water.

- Evolution of combined water in the argillaceous components.

- Calcination of the calcium carbonate (CaCO3) to calcium oxide (CaO).

- The reaction of CaO with silica to form dicalcium silicate.

- The reaction of CaO with the aluminum and iron-bearing constituents forms the liquid phase.

- Formation of the clinker nodules.

- Evaporation of volatile constituents (e.g., sodium, potassium, chlorides, and sulfates).

- The reaction of excess CaO with dicalcium silicate forms tricalcium silicate.

The above events can be condensed into four major stages based on the change in temperature inside the kiln:

- 100°C (212°F): Evaporation of free water

- 100°C (212°F)-430°C (800°F): Dehydration and formation of oxides of silicon, aluminum, and iron

- 900°C (1650°F)-982°C (1800°F): CO2 is evolved and CaO is produced through calcination

- 1510°C (2750°F): Cement clinker is formed

The kiln is angled by 3 degrees to the horizontal to allow the material to pass through it, over a period of 20 to 30 minutes. By the time the raw mix reaches the lower part of the kiln, clinker forms and comes out of the kiln in marble-sized nodules.

Stage 5: Cooling and final grinding

After exiting the kiln, the clinker is rapidly cooled down from 2000°C to 100°C-200°C by passing air over it. At this stage, different additives are combined with the clinker to be ground in order to produce the final product, cement.

Gypsum added to and ground with clinker regulates the setting time and gives the most important property of cement, compressive strength. It also prevents agglomeration and coating of the powder at the surface of balls and mill walls.

Some organic substances, such as Triethanolamine (used at 0.1 wt.%), are added as grinding aids to avoid powder agglomeration. Other additives sometimes used are ethylene glycol, oleic acid, and dodecyl-benzene sulphonate.

The heat produced by the clinker is circulated back to the kiln to save energy. The last stage of making cement is the final grinding process. In the cement plant, there are rotating drums fitted with steel balls.

Clinker, after being cooled, is transferred to these rotating drums and ground into such a fine powder that each pound of it contains 150 billion grains. This powder is the final product, cement.

Stage 6: Packing and Shipping

Cement is conveyed from grinding mills to silos (large storage tanks) where it is packed in 20-40 kg bags. Most of the product is shipped in bulk quantities by trucks, trains, or ships, and only a small amount is packed for customers who need small quantities.

Chemical Reactions during Cement Manufacturing Process

The reactions that take place (after evaporation of free water) between the reactants in the kilning phase of the cement making process are as follows:

- Clay Decomposition:

Si2Al2O5(OH)2 → 2 SiO2 + Al2O3 + 2 H2O (vapor)

KAlSi3O8 (orthoclase) + 0.5 SO2 + 0.25 O2 → 3 SiO2 + 0.5 Al2O3 + 0.5 K2SO4 - Dolomite Decomposition:

CaMg(CO3)2 → CaCO3 + MgO + CO2

KMg3AlSi3O10(OH)2 + 0.5 SO2 + 0.25 O2 → 0.5 K2SO4 + 3 MgO + 0.5 Al2O3 + 3 SiO2 + H2O (vapor) - Low-Temperature Calcite Decomposition:

2 CaCO3 + SiO2 → Ca2SiO4 + 2 CO2

2 MgO + SiO2 → Mg2SiO4

Ca5(PO4)3OH + 0.25 SiO2 → 1.5 Ca3(PO4)2 + 0.25 Ca2SiO4 + 0.5 H2O (vapour) - Alumina and Oxide Reaction:

12 CaCO3 + 7 Al2O3 → Ca12Al14O33 + 12 CO2

4 CaCO3 + Al2O3 + Fe2O3 → Ca4Al2Fe2O10 + 4 CO2

4 CaCO3 + Al2O3 + Mn2O3 → Ca4Al2Mn2O10 + 4 CO2 - The reaction of Remaining Calcite:

CaCO3 → CaO + CO2 - Sintering:

Ca2SiO4 + CaO → Ca3SiO5

Also Read: Material Processing | Definition and Examples

Uses of Cement

Some of the numerous uses of cement are as below.

- It is used in mortar for plastering, masonry work, pointing, etc.

- It is used for making joints for drains and pipes.

- It is used for a water-tightness of structure.

- It is used in concrete for laying floors, and roofs and constructing lintels, beams, stairs, pillars, etc.

- It is used where a hard surface is required for the protection of exposed surfaces of structures against the destructive agents of the weather and certain organic or inorganic chemicals.

- It is used for precast pipes manufacturing, piles, fencing posts, etc.

- It is used in the construction of important engineering structures such as bridges, culverts, dams, tunnels, lighthouses, etc.

- It is used in the preparation of foundations, watertight floors, footpaths, etc.

- It is employed for the construction of wells, water tanks, tennis courts, lamp posts, telephone cabins, roads, etc.

Raw Materials for Cement

Raw material ingredients used for manufacturing Portland Cement are:

- Calcareous Materials: Calcareous Materials are compounds of calcium and magnesium. Limestones are a common calcareous material used in manufacturing cement.

- Argillaceous Materials: Argillaceous Materials are mainly silica, alumina, and oxides of iron. Clay and shale are the common argillaceous material used as cement ingredients in the process of manufacturing cement.

Also Read: Construction Terminologies You Should Know

Properties of Good Cement

It is always desirable to use the best cement in construction. Therefore, the properties of cement must be investigated. Although desirable cement properties may vary depending on the type of construction, generally a good cement possesses the following properties (which depend upon its composition, thoroughness of burning, and fineness of grinding).

- Provides strength to masonry.

- It Stiffens or hardens early.

- Possesses good plasticity.

- An excellent building material.

- Easily workable.

- Good moisture-resistant.

Proper field tests and laboratory tests should be done to ensure the quality of the cement.

Also Read: Concrete |Definition, Ingredients and Curing You Should Know

Field Test of Cement

Sometimes it may be required to perform cement quality tests at a site within a very short period of time for evaluating the condition of the supplied cement. In most cases, it is not possible to have any laboratory test in a short period of time.

Therefore, the quality check is performed with the help of some basic field tests. Although these tests are not very accurate, they provide some basic ideas to a civil engineer regarding the quality of the cement.

Field Tests of Cement for Civil Engineers

- Date of Manufacturing: As the strength of cement reduces with age, the date of manufacturing of cement bags should be checked.

- Cement Color: The color of cement should be uniform. It should be typical cement color i.e. gray color with a light greenish shade.

- Whether Hard Lumps are Formed: Cement should be free from hard lumps. Such lumps are formed by the absorption of moisture from the atmosphere.

- Temperature Inside Cement Bag: If the hand is plunged into a bag of cement, it should be cool inside the cement bag. If a hydration reaction takes place inside the bag, it will become warm.

- Smoothness Test: When cement is touched or rubbed in between fingers, it should give a smooth feeling. If it felt rough, it indicates adulteration with sand.

- Water Sinking Test: If a small quantity of cement is thrown into the water, it should float for some time before finally sinking.

- The smell of Cement Paste: A thin paste of cement with water should feel sticky between the fingers. If the cement contains too much-pounded clay and silt as an adulterant, the paste will give an earthy smell.

- Glass Plate Test: A thick paste of cement with water is made on a piece of a glass plate and it is kept under water for 24 hours. It should set and not crack.

- Block Test: A 25mm × 25mm × 200mm (1”×1”×8”) block of cement with water is made. The block is then immersed in water for three days. After removal, it is supported 150mm apart and a weight of 15kg is uniformly placed over it. If it shows no sign of failure the cement is good.

Also Read: What is Mortar? | Uses and Tests

Storage of Cement: Procedures, Protection, Duration

Storage of cement is predominant for construction works. For the economy and proper flow of work, it is a very common practice to buy a bulk amount of cement at a time. Hence, it is essential to ensure correct arrangements to store properly this amount of cement. Properly maintained storage facilities preserve the quality and fitness of the cement to be used.

Cement may be an absorbent construction material. It reacts with wetness either in liquid or in vapor forms quickly. In the presence of wetness, cement undergoes a chemical process termed hydration. Cement becomes useless once the hydration method has taken place. Cement will stay in shape as long as it encounters wetness. Moisture may be a huge enemy of cement and thus cement luggage never keep for an extended amount.

Why it is Important to Properly Store Cement?

Storing cement is very important because of its own quality, use and while we have bought the cement, the consecutive step is storing it properly,

Moisture Effect on Cement Strength

If cement is not stored properly, it will absorb moisture from the regional air or the other supply, inflicting the cement to react with it with chemicals. The binding property and strength of cement depend upon its capability for the chemical process. For this, the strength of cement is going to be affected.

Storage Duration Effect on Cement Quality

Prolonged storage of cement, wherever dampish air could gain access, decreases the strength of the cement and makes it seem to be coarser, the quantity of water needed to create a neat cement paste of normal consistency will increase, and setting time is additionally accrued. In worst cases, lump formation even renders the cement unusable.

To hindrance of cement against deterioration and retentive its freshness, its storage ought to be specified no dampness or moisture is allowed to succeed in cement either from the bottom, walls, or from the setting. This becomes necessary throughout the wet season and in coastal regions once regional air contains the next quantity of moisture in it.

Also Read: Brick Masonry | Advantages and Disadvantages In 2023

Procedures of Cement Storage

Following are some basic points that one ought to be considered when storing cement:

- Cement baggage ought to be held on wherever no wetness or moistness is allowed to succeed in cement either from the bottom, walls or from the surroundings, etc.

- Do not enable hooks to facilitate the storage of cement. Exploitation hooks have been marked as a harmful follow for the handling of baggage because it exposes the cement to the open atmosphere, which can be damp and misty.

- Never store the cement bags with fertilizers or a different product, as any contamination will affect the standard and performance of the screen.

- Avoid storage of cement within the basement; ideally, the storage ought to be drained on the primary or higher floors.

- The little windows are provided at sill level and are commonly unbroken and tightly shut. Because of this, the wet or rainwater is prevented from stepping into the shed.

Protection Steps for Proper Storage of Cement

Cement should be taken care of rigorously and seriously. There are some steps to be considered as precautions for storing cement. Below steps are for storing cement:

- Climatic moisture comfortable

- Endurance of cement storage

- Place, site, or zone of storage

- Organizing cement bags

- Disengagement of cement bags

A brief description of these cement protection steps is given below. In all cement storage facilities, these precautions must be considered.

Climatic Moisture Comfortable

Climatic or atmospheric moisture comfortable is most bizarre and important for storing cement. The presence of moisture in the climate would be damaged cement and it becomes useless material. Storing cement must be kept in an airtight workplace or worksite in the godown. The intake of moisture from the climate also depends on the quality and quantity of cement. For this, extra care must be taken to keep the cement fresh and well. If there, is any chance of exposure to airtightness, then cement tests must be taken for verification. If the result shows, more than 5% moisture then it is not used for construction work.

Endurance of Cement Storage

While storing cement, time is the most important factor for better easement. Longtime storage could be damaged cement. It would be a great use if cement was not stored for more than 3 months. Hence, long-timing stored cement can be reduced its strength of cement.

The below chart is the duration and devaluation of stored cement’s strengths. Such as:

| Times of storage | Natural phase(in percentage) | 3 months(in percentage) | 6 months(in percentage) | 1 year(in percentage) | 5 years(in percentage) |

| Devaluation in strength at 28 days | 0% | 20% | 30% | 40% | 50% |

Place, Site, or Zone of Storage

Special and customized places like- godowns or warehouses at worksites are good for cement storage. Open places are damaged by cement usage. The design of godowns or warehouses should be well-structured. The main purposes of making a special typed storage place for cement are ‘climate adjustment’ and ‘time state’. Godowns should be well drainage, waterproof room, and attached with small windows in the storerooms.

Organizing Cement Bags

For designing a storeroom for cement, like godowns, should be preferably made of wooden stuff. The wooden storeroom is perfect for atmospheric adjustment for collecting and storing cement for longer periods. Hence, organizing and gathering cement bags depends on the condition and situation of the storeroom.

The cement should be placed on a wooden platform above 150 mm to 200 mm from the floor ground. Each bundle of cement bags should be connected tightly so that air cannot pass through or enter it. of course, manufacture dates and places should be mentioned on the bags, so that workers can understand the condition of cement.

Disengagement of Cement Bags

While the time of using cement bags, there should be considered to use the very first bag and then the second, then the third, and so on. Removing cement from bags should be done carefully according to climatic comfortable.

In the end, the usage of cement and storing cement bags at worksites like- godowns is incredibly necessary for construction work. Therefore, cement bag collection, organizing, time, and placing the cement, planning godown; all at once are counted as parts and instrumentation to create the cement storeroom or the steps of storage of cement.

Also Read: Walls: Load Bearing Wall and Non Load Bearing Wall

Fineness of Cement

The size of the particles of the cement is its fineness. The required fineness of good cement is achieved through grinding the clinker in the last step of the cement production process. As the hydration rate of cement is directly related to the cement particle size, the fineness of cement is very important.

Importance of Cement Fineness

- The fineness of cement affects the hydration rate, and in turn, the strength. Increasing fineness causes an increased rate of hydration, high strength, and high heat generation.

- Bleeding can be reduced by increasing fineness. However, increased fineness can also lead to the requirement of more water for workability, resulting in a higher possibility of dry shrinkage.

- The increased surface area-to-volume ratio will ensure a more available area for water-cement interaction per unit volume.

Fineness Test of Cement

- AASHTO T 98 and ASTM C 115: Fineness of Portland Cement by the Turbidimeter.

- AASHTO T 128 and ASTM C 184: Fineness of Hydraulic Cement by the 150-mm (No.100) and 75-mm (No. 200) Sieves

- AASHTO T 153 and ASTM C 204: Fineness of Hydraulic Cement by Air-Permeability Apparatus o AASHTO T 192 and

- ASTM C 430: Fineness of Hydraulic Cement by the 45-mm (No. 325) Sieve.

Also Read: Cladding: Types and Considerations In 2023

Cement Manufacturing Industries In The World

As of 2010, the top three cement producers in the world are the USA, China, and India. Among these countries, China alone manufactures about 45% of the total worldwide production of cement.

It is a non-recyclable product and so every new construction or repair needs new cement, thus global consumption continues to rise. Especially in the economies of Asia and Eastern Europe, cement production is an important element of progress.

According to the global cement directory, there are about 5673 active cement production plants in the world; among these, 3900 are in China.

Some of the leading cement manufacturers are Lafarge Holcim, Heidelberg Cement, Cemex, Italcementi, China Resources Cement, Taiwan Cement, Eurocement, Votorantim, etc. The total global consumption of cement, as indicated by statistics in 2015, measures up to 18 million metric tons, most of which is attributed to the rising national economy of North America.

The leading producers of cement among the developed capitalist countries are the USA, France, Italy, and Germany. Iran, now the top producer in the Middle East, occupies the third position in the world for cement manufacture.

Asian and African countries are also progressive in the production of cement. The kiln process in cement plants causes the emission of carbon dioxide, which is one of the major greenhouse gases responsible for global warming.

With a view to reducing, even eliminating, the harmful environmental impacts of cement usage, leading industries are now trying to implement technologies that utilize recycled materials and renewable energy sources. “Green cement” is such a sustainable construction material that is the result of extensive research related to minimizing the effects of global warming.

Also Read: Difference Between Architect and Civil Engineer

Specific Gravity of Cement

Mainly Specific Gravity is the ratio of the density of a substance to the density of a reference substance at a fixed temperature. In other words, it is the ratio of the mass of a substance to the mass of a reference substance. And the theme is also the same for cement. The specific Gravity of cement is the ratio of the density or mass of cement to the density or mass of a reference substance.

But in both of the state’s densities or masses, the volume should be the same. If the volume does not remain the same the specific gravity has no existence then. Because the mass or density will be changed of the substance or reference substance.

Why We Calculate Specific Gravity of Any Substance

We calculate the specific gravity of any substance to know the behavior of the material in water. And we can know if the material will sink or floats in the water. All of the materials in our environment have a fixed specific gravity.

The usual range is 1-100. If the specific gravity is greater than 1, then it sinks in water. If the specific gravity Is less than 1 it floats in water. So if the specific gravity of any substance is known to us we can use the materials in suitable places for any work.

Basically, specific gravity defines that the substance is how much heavier than water or a reference substance of the same volume. The specific gravity of cement ranges from 3.1 to 3.16 g/cc.

By this statement, we can ensure that cement is 3.1-3.16 times heavier than water of the same volume. And it sinks in water. Because the specific gravity is greater than 1.

Every material consists of so many little pores, which may contain voids in it. And a material becomes useless when any void is present in the material. If the cement is covered by extreme moisture content due to bad weather conditions, then the specific gravity of the cement may go up to 3.19.

If the specific gravity value reaches 3.19, then the pores in cement are filled with moisture. Cement undergoes a chemical reaction when it is reacted with atmospheric moisture this process is termed hydration.

Moisture is very harmful to cement. Cement becomes useless once it is hydrated with water. The presence of excessive moisture is the reason for finding a lot of lumps in old cement due to the content in it.

Standard Value of Specific Gravity of Cement

The specific gravity value of portland cement is generally around 3.15 while the specific gravity value of portland-blast-furnace-slag and portland-pozzolan cements may have specific gravities near 2.90.Portland Cement Association (PCA). (1988). Design and Control of Concrete Mixtures.

Portland Cement Association

Reference Substances for Specific Gravity

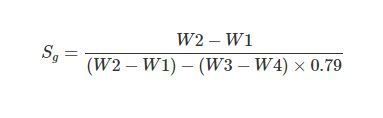

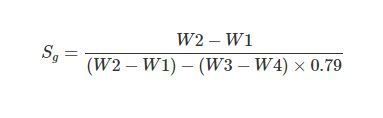

Maximum time water is used as a reference substance. And its temperature should be near 4°C. For gases, it is air at room temperature of 25°C. But if “Cement” is used as a sample substance then kerosine would be the reference substance. Because cement hydrates and forms calcium oxide when it reacts with water. But kerosene won’t show any reaction when it is mixed with cement. The specific gravity of kerosine is 0.79 g/cc.

How to Calculate Cement-Specific Gravity?

One can easily determine the value of the specific gravity of cement using the Le Chatelier Flask method. Determination of the specific gravity of cement at the site level can be easily done using this experiment.

Required Materials & Apparatus

The followings are the specific gravity test apparatus and materials:

- Kerosene

- Ordinary Portland Cement

- Le-Chatelier Flask of 250 ml or Specific Gravity Bottle / Pycnometer of 100 ml

- Weighing balance with 0.1 gm accurate

Specific Gravity Test Procedure for Cement

The specific gravity test procedure contains only four steps. Followings are the four steps to be followed to perform a specific gravity test of cement:

- The Flask should be free from the liquid which means it should be fully dry. Weigh the empty flask. Which is W1.

- Next, fill the cement on the bottle up to half of the flask around 50gm and weigh it with its stopper. And it is W2.

- Add Kerosene to the cement up to the top of the bottle. Mix well to remove the air bubbles in it. Weigh the flask with cement and kerosene. And it is W3.

- Empty the flask. Fill the bottle with kerosene up to the top and weigh the flask for counting W4.

Cement-specific gravity formula:

Difference Between OPC and PPC Cement

PPC cement’s full form is Portland Pozzolana Cement.

OPC cement’s full form is Ordinary Portland Cement.

Both PPC and OPC cement is used in construction. PPC cement is a variant of OPC cement. These two types of cement differ from each other in terms of component, strength, heat generation, the percentage of several components, durability, grades, cost, eco-friendly nature, application, setting time, curing period, etc. The main OPC and PPC cement differences are written below.

Also Read: Theory of Structures To Know In 2023

Difference Between OPC and PPC Cement

In the following table, the main differences between OPC and PPC cement are given:

| Sources | OPC Cement | PPC Cement | |

|---|---|---|---|

| 1 | Definition/ Components | A mixture of limestone and other raw materials like argillaceous, calcareous, and gypsum is prepared and then ground to prepare OPC (Ordinary Portland Cement). | PPC (Portland Pozzolana Cement) is prepared by adding Pozzolanic materials to OPC. So, the main components are OPC clinker, gypsum, and pozzolanic materials (15~35%) which include calcined clay, volcanic ash, fly ash, or silica fumes. |

| 2 | Strength | Initial strength is higher than PPC. | PPC concrete has higher strength than OPC concrete over a longer period of time. |

| 3 | Heat of hydration | Generates more heat than PPC in hydration reaction which makes it less suitable for mass casting. | It has a slow hydration process and thus generates less heat than OPC. |

| 4 | Durability | OPC concrete is less durable in aggressive weather. | PPC concrete is more durable in aggressive weather. |

| 5 | Cost | Costlier than PPC. | Cheaper than OPC. |

| 6 | Environmental Impact | Emits CO2 during the manufacturing process. | It constitutes industrial and natural waste which makes it eco-friendly. |

| 7 | Application/ uses | It is suitable where fast construction is required but not suitable for mass concreting due to heat issues as mentioned above. | It is suitable for all types of construction work. For example RCC casting of buildings, mass concreting for bridges, and even plastering and other non-structural works. |

| 8 | Setting Time | Lower than PPC. Its initial setting time is 30 minutes and the final setting time is 280 minutes. Its faster setting time helps faster construction. | The setting time of PPC portland is higher than OPC. Its initial setting time is 30 minutes and the final setting time is 600 minutes. Its slower setting time helps to get better finishing. |

| 9 | Fineness | OPC has a finiteness of 225 sq.m/kg. It has lower fineness than PPC. So, it has higher permeability resulting in lower durability. | OPC has a finiteness of 300 sq.m/kg. It has higher fineness than OPC. So, it has lower permeability resulting in higher durability. |

| 10 | Grades available | 33 Grade, 43 Grade, and 53 Grade OPC cement are available. | No specified grade of PPC cement is available. |

| 11 | Workability | Lower than PPC. | Higher than OPC. |

| 12 | Resistance against chemical attack | It has lower resistance against alkalis, sulfates, chlorides, etc. | It has higher resistance against alkalis, sulfates, chlorides, etc. |

Also Read:Engineering Ethics

Cement Storage Godown/ Warehouse Requirements

Storage of cement is predominate for constructional works. Hence, correct arrangements for storing the cement for constructions come are needed. It preserves its quality and fitness of cement to be used.

Cement may be an absorbent construction material. It reacts with wetness either in liquid or in vapor forms quickly. In the presence of wetness, cement undergoes a chemical process termed as hydration. Cement becomes useless once the hydration method has taken place. Cement will stay in shape as long because it encounters wetness. Moisture may be a huge enemy of cement and thus cements luggage never keep for an extended amount.

Requirements of a Godown/ Warehouse Used for Cement Storage

For the sake of the building materials’ higher quality, each material ought to have a godown or warehouse for storage. Below are the subsequent characteristics of a godown or warehouse to store cement at work sites. Such as:

- A godown would not allow dampness to urge to cement.

- Godown or warehouse itself ought to be sited in a very strategic purpose that will create it simple for providers to urge to get the good condition of cement. This implies the storeroom ought to be sited solely wherever it will not be tough for trucks to urge merchandise to employees.

- Space ought to be created accessible so, throughout stocking, loaders will simply drop off bags with ease.

- Lighting ought to be created accessible also.

- Godown or warehouse should not be specified moisture would emerge from the ground to satisfy the equipped products.

- The warehouse should have enough workforce to facilitate the movement of products in and out of the warehouse.

We hope this article helped you learn about the Cement | Types, Composition, And All You Need to Know. You may also want to learn about Concrete |Definition, Ingredients, and Curing You Should Know, Reinforced Cement Concrete, 12 Most Expensive Colleges /Universities In The World, and 16 Different Types of Concrete You Should Know Right Now.

If you liked this article, please Join WebsiteForEngineers on Telegram, and you can also find us on Pinterest, Twitter, and Facebook.