Last Updated on June 6, 2023 by Eng Katepa

Reinforced Cement Concrete is basically concrete in which steel bars of desirable magnitude is introduced in the casting stage so that the resulting composite material resists the stresses developed due to the external loads.

In flexural members, the steel reinforcement is generally provided near the tension face to resist the tensile stresses since the tensile strength of concrete is hardly one-tenth of its compressive strength. In the case of compression members, the steel reinforcement is distributed uniformly in the cross-section to resist the compressive stresses developed due to the external loads.

The two materials – concrete and steel – act together in resisting external forces, such as wind, vibrations, earthquakes, and all other causes of tensile and shear stresses, thus preventing the concrete to crack, crumble, or break altogether.

The revolutionary engineering concept of reinforcing the weak tensile zone of concrete with steel reinforcement was developed in the mid-nineteenth century. The early 20th century witnessed significant improvements in the development and use of reinforced concrete mainly due to the production of good quality concrete with improved strength and improved quality of steel with surface characteristics suitable to develop a good bond between concrete and steel.

The success of reinforced concrete as a revolutionary material for use in various types of structures is mainly due to the improved quality of concrete and steel over the years and also the improved bond characteristic between the two ingredients.

Historical Development of Reinforced Cement Concrete

The present state of development in the field of reinforced concrete is due to the continuous research done by scientists and engineers in this field during the last 150 years. Isaac Johnson first made the prototype of modem cement in 1845, by burning a mixture of clay and chalk until clinkering, so that reactions necessary for forming strong cementitious compounds are complete.

The early 20 century witnessed the development of mass production of good quality cement. At present Ordinary Portland cement of various strengths designated as C-33, C-43, and C-53 are available for use in different types of structures. Different types of cement with specific properties have been factors in the working loads.

Several Investigators like Emperger (1936), Whitney (1937), Jenson (1943), Chambaud (1949), and Hognestad ( 1951 ) developed the ultimate load theory based on different types of stress blocks. Reinforced concrete structures designed solely on the basis of ultimate load theory resulted in slender structural elements and their serviceability characteristics (deflections and cracks) under working loads were not within codified acceptable limits.

The ultimate load method of design ensures the safety of the structures against the collapse limit state only and as such as does not give any information about the behavior of the structure at service loads and the range between service and collapse loads. The inadequate ultimate load method in not ensuring the serviceability of the structure resulted in the development of a limit state design.

The philosophy of limit state design was first incorporated into the Russian code in 1955. Basically, limit state design is a method of designing structures based on a statistical concept of safety and the associated statistical probability of failure. Limit state design is based on the concept of probability and comprises the application of the method of statistics to the variations that occur in practice in the loads acting on the structure and the strength of the materials.

The Limit state design overcomes the inadequacies of the working stress and ultimate load methods, ensures the structure’s safety against excessive deflections and cracking under service loads, and provides for the desired load factor against failure. Hence, the British Code, American Code, Australian Code, German Code, Euro Code, and Indian code have adopted the limit state design concepts.

Philosophy of Structural design

The main objective of reinforced concrete structural design is to comply with the following essential requirements.

- Structures designed should satisfy the criterion, of desirable ultimate strength, in flexure, shear, compression, tension, and torsion developed under a given system of loads and their combinations. In addition, the stresses developed in the structure under the given system of loads should be within the safe permissible limits under service loads.

- The structure designed should satisfy the criterion of serviceability, which limits the deflections and cracking to be within acceptable limits. The structure should also have adequate durability and impermeability, resistance to acids, corrosion, frost, etc.

- The structure should have adequate stability against overturning, sliding, buckling, and vibration under the action of loads.

A satisfactory structural design should ensure the three basic criteria of strength, serviceability, and stability. In addition, the structural Engineer should also consider aesthetics and economy. The structural engineer and the architect should coordinate so that the structure designed is not only aesthetically superior but also strong enough to safely sustain the designed loads without any distress during the lifetime of the structure.

Applications of Reinforced Cement Concrete

Reinforced cement concrete is well established, as an important construction material often preferred to steel construction mainly due to its versatility, adaptability, and resistance to fire and corrosion resulting in negligible maintenance costs. The development of better quality cement during the last decade has resulted in stronger and more durable concrete for use in different types of structures.

- Reinforced cement concrete is ideally suited for the construction of floor and roof slabs, columns, and beams in residential and commercial structures.

- The present trend is to adopt reinforced concrete for bridges of small, medium, and long spans resulting in aesthetically superior and economical structures in comparison with steel bridges.

- Typical use of reinforced concrete in earth retaining structures includes abutments for bridges and retaining walls for earthen embankments.

- Reinforced cement concrete is ideally suited for water-retaining structures like ground and overhead tanks and hydraulic structures like gravity and arch dams. The material is widely used for the construction of large domes for water tanks and sports stadiums and conference halls.

- Reinforced cement concrete grid floors comprising beams and slabs are widely used for covering large areas like conference halls where column-free space is an essential requirement.

- For aircraft hangers, reinforcement concrete shells comprising thin circular slabs and deep edge beams provide an economical solution.

- Reinforced cement concrete folded plate construction has been used for industrial structures where large column-free space is required under the roof.

- In coastal areas where corrosion is imminent due to the humid environment, reinforced concrete is ideally suited for the construction of marine structures like wharves, quay walls, watchtowers, and lighthouses. For warehouses in coastal areas, reinforced cement concrete trusses are preferred to steel trusses.

- Reinforced concrete poles have almost replaced steel poles for power transmissions. Tall towers for T.V. transmission are invariably constructed using reinforced cement concrete.

- Multistorey reinforced concrete buildings are routinely adopted for both residential and office complexes. For heavy-duty floors in factories, reinforced concrete is ideally suited due to its resistance to wear and tear and improved durability.

- In atomic structures, reinforced concrete is preferred to steel for pressure vessel construction due to the superior radiation absorption characteristics of high-strength and high-density concrete.

- Reinforced concrete piles, both precast, and cast-in sites have been in use for foundations of structures of different types like bridges and buildings.

- Another novel application of reinforced concrete is in the construction of pavements for highways and airport runways.

The Twentieth century has witnessed reinforced concrete as a revolutionary material suitable for the construction of most simple to complex structures. With significant improvements in the quality of cement and steel, reinforced concrete will continue to find new applications and widespread use in the 21st century.

Reinforced Cement Concrete Structural system

Any type of structure may be considered an assemblage of various structural elements, which perform a predetermined function of resisting various types of forces. Basically, a structure can be built up using structural and non-structural elements. The structural elements (beams, slabs columns, etc.) have the primary function of resisting the external loads, while the nonstructural elements (partitions, false ceilings, doors, etc.) do not support the external loads.

Basically, the structural elements can be classified as one-dimensional elements (such as beams, columns, arches, etc) or two-dimensional elements (such as slabs, plates, shells, etc.), and three-dimensional elements (such as thick pipes, walls of nuclear reactor vessels, domes, etc.)

Circular girders generally used in water tanks are subjected to combined flexure, shear, and torsion while the comer columns in a multistorey framed structure are subjected to biaxial bending.

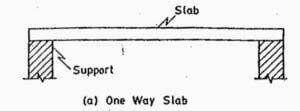

- One-way Slab Systems

The figure below shows the floor system comprising a one-way slab supported at the edges by walls or beams and supports dead and live loads. The slabs are subjected primarily to maximum flexure at the center of the span along the shorter direction and maximum shear at supports under gravity loads.

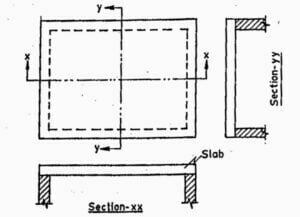

- Two-Way Slab Floor Systems

The figure below shows a typical two-way slab floor system commonly used in buildings. In this case, the slab is supported at the edges and it is subjected to flexure in two principal directions while resisting gravity loads.

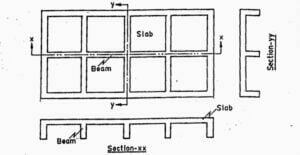

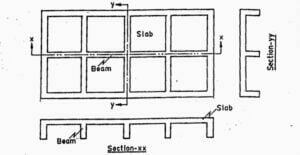

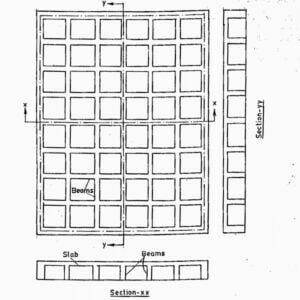

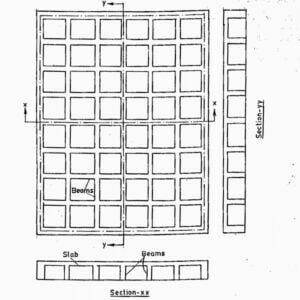

- Beam and Slab floor systems

The figure above shows a typical beam and slab floor system generally used in residential and commercial building structures. In this case, the gravity loads are resisted by the flexure of the slab and beams.

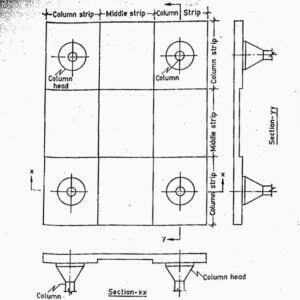

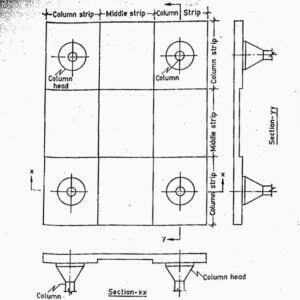

- Flat Slab Floor System

The figure above shows a flat slab floor system in which the slab is supported on columns directly without any beams. This type of floor system is generally preferred for large-span office complexes, commercial buildings, and garages, where headroom is less.

- Grid Floor system

The figure above shows a typical grid floor system comprising beams spaced at short intervals running in perpendicular directions and supporting a thin slab. This type of roof is generally used for large conference hall and commercial buildings that requires column-free space. The grid floor is supported on solid walls or columns at regular intervals.

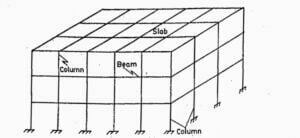

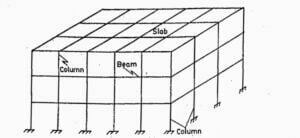

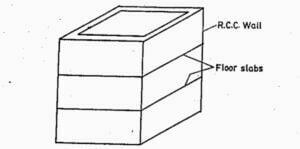

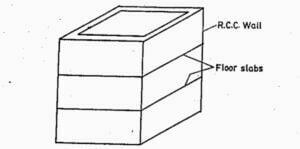

- Multistorey Vertical Framing System

The figure shows the multistorey vertical frame comprising columns, beams, and slabs forming a three-dimensional structure. The gravity loads are transmitted from the slab to beams which in turn transfer the loads to columns and dually to the foundations. The rigid column and beam frame can resist floral loads due to wind.

- Shear Wall System

This system consists of solid concrete walls covering the full height of the building. Generally, the shear wall box is located in the lift/ staircase regions. Sometimes the shear walls are located as Exterior or interior walls placed along the transverse direction of the tall building to resist lateral loads due to wind.

Design Codes

- Objective of Codes

Based on extensive research and practical knowledge, various countries have evolved their national codes, which serve as guidelines for the design of structures. The main objectives of the codes are

- To provide adequate structural safety by ensuring strength ability and durability.

- To specify simple design procedures, design tables and formulae for easy computations.

- To provide legal validity and to protect structural engineers from any liability due to failures of structures caused by inadequate design and improper materials and lack of proper supervision during construction.

- To provide a uniform set of design guidelines to be followed by various structural designers in a particular country.

National building codes are periodically revised to reflect the improvements in the quality of materials and design procedures evolved as a result of comprehensive research investigations conducted in the institutions in the country and abroad.

2. Design Code

All reinforced concrete structural designs in India should conform to the recently revised Indian Standard Code IS:456-2000 Code of practice for plain and reinforced concrete (Fourth Revision). The corresponding national codes of other countries are often referred to as the American Concrete Institute Code (ACI- 318) and the British Code BS- 8110 of 1985 and 1995 as well as the Euro Code.

Loading Standards

- Dead loads

These are loads that will not change with respect to time. The dead loads acting on the structure include the self-weight of the structural elements, partitions, and finishes, which depends upon the type of material used in the structure.

- Live loads

These are loads that change with respect to time. Live or imposed loads include the loads due to people occupying the floor and those due to materials stored or vehicles on garage floors.

- Wind loads

Wind loads have to be considered in the design of multistorey buildings, towers, and poles.

- Snow Loads and Local Combinations

Structures subjected to snow loads1 have to be designed suitably by considering the snow loads prevailing in the region and also the various load combinations.

- Earth Quake Loads

Seismic or earthquake forces have to be considered in the design of structures located in seismic zones.

Advantages of Reinforced Cement Concrete

The following are the advantages of Reinforced Concrete

Strength; Reinforced Cement Concrete has very good strength in tension as well as compression.

Durability; Reinforced Cement Concrete structures are durable if designed and laid properly. They can last up to 100 years.

Mouldability; Reinforced Cement Concrete sections can be given any shape easily by properly designing the formwork. Thus, it is more suitable for architectural requirements.

Ductility; The steel reinforcement imparts ductility to the Reinforced Cement Concrete structures.

Economy; Reinforced Cement Concrete is cheaper as compared to steel and prestressed concrete. There is an overall economy by using R.C.C. because its maintenance cost is low.

Transportation; The raw materials which are required for Reinforced Cement Concrete i.e., cement, sand, coarse aggregate, water, and steel are easily available and can be transported easily. Nowadays Ready Mix Concrete (RMC) is used for faster and better construction. (RMC is concrete that is manufactured in the factory and transported to the site in a green or plastic state).

Fire Resistance; Reinforced Cement Concrete structures are more fire-resistant than other commonly used construction materials like steel and wood.

Permeability; Reinforced Cement Concrete is almost impermeable to moisture.

Maintenance; Concrete structures require low maintenance after completion of work as compared to structures made of steel and timber.

Rigidity; As Reinforced concrete are stiff; they provide good rigidity.

Disadvantages of Reinforced Cement Concrete

Reinforced Cement Concrete has the following disadvantages :

- Reinforced Cement Concrete structures are heavier than structures of other materials like steel, wood, glass, etc.

- Reinforced Cement Concrete needs a lot of formwork, centering, and shuttering to be fixed, thus requiring a lot of site space and skilled labor.

- Concrete takes time to attain its full strength. Thus, unlike steel structures, R.C.C. structures can’t be used immediately after construction.

We hope this article helped you learn about Reinforced Cement Concrete. You may also want to learn about Home Furniture | Meaning and Type, Best Engineering Books For Engineers, Home Furniture | Meaning and Type, and The Best Garden Hoses of 2022

If you liked this article, please Join WebsiteForEngineers on Telegram, and you can also find us on Pinterest, Twitter, and Facebook.