Brick masonry is a sturdy form of construction where bricks are systematically placed in a mortar to create a solid structure.

Brick is one of the most durable and versatile building materials for commercial and residential homes.

Furthermore, Brick masonry is built with bricks bonded together with mortar. For temporary sheds, mud mortar may be used, but lime or cement mortars are used for all permanent buildings.

The various types of bonds generally used in brick masonry are;

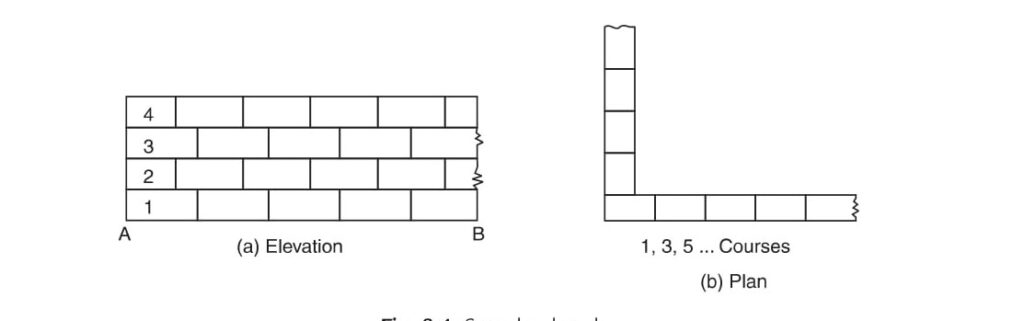

- Stretcher Bond: A stretcher is the long face of the brick as seen in the elevation. In the brick of size, 190 mm × 90 mm × 90 mm, 190 mm × 90 mm face is the stretcher. In stretcher bond masonry all the bricks are arranged in stretcher courses as shown in Fig. 1. However, care should be taken to break vertical joints. This type of construction is useful for the construction of half-brick-thick partition walls.

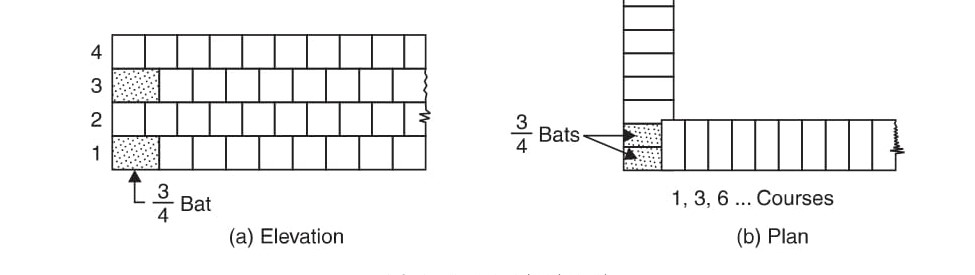

- Header Bond: A header is the shorter face of the brick as seen in the elevation. In a standard brick, it is a 90 mm × 90 mm face. In header bond brick masonry all the bricks are arranged in the header courses as shown in Fig. 2 below. This type of bond is useful for the construction of brick thick walls.

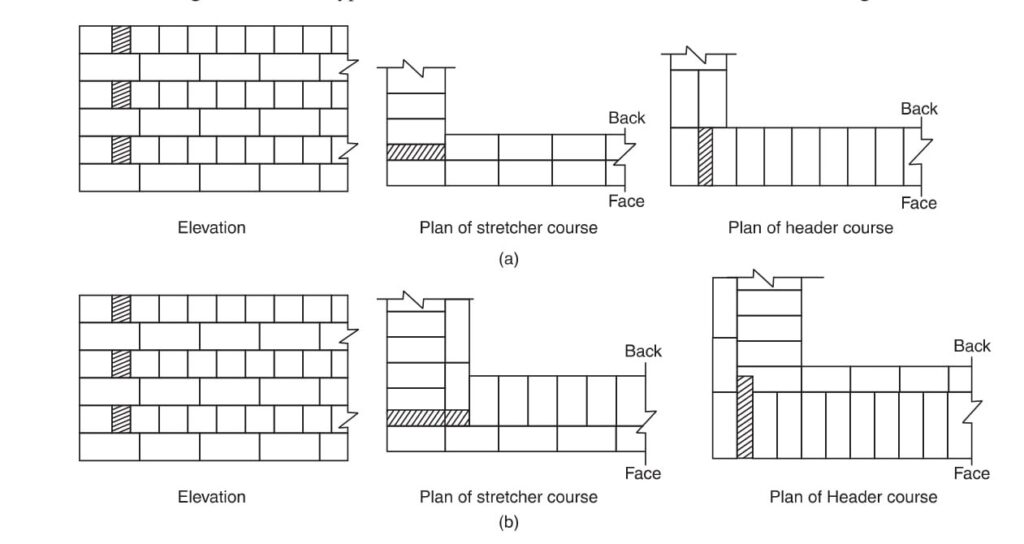

- English Bond: These alternate courses consist of headers and stretchers. This is considered to be the strongest bond. Hence it is a commonly used bond for walls of all thicknesses. To break the continuity of vertical joints a brick is cut lengthwise into two halves and used at the beginning and end of a wall after the first header. This is called Queen Closer. Fig. 3 below shows a typical one-brick and one-and-a-half brick-thick wall with English bonds.

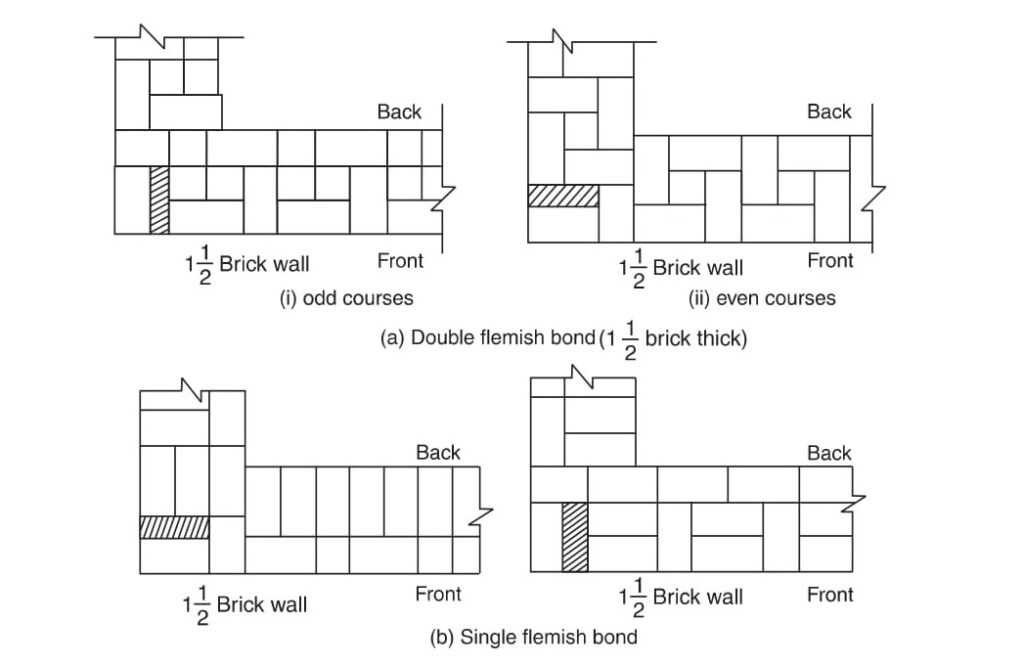

- Flemish Bond: In this type of bond each course comprises of alternate header and stretcher Fig. 4. Alternate courses start with a stretcher and header. To break the vertical joints queen closers are required if a course starts with a header. Every header is centrally supported on the stretcher below it. Flemish bonds may be further classified as: Double Flemish Bond, and Single Flemish Bond.

Also Read: Concrete |Definition, Ingredients and Curing You Should Know

Also Read: What is Mortar? | Uses and Tests

Table of Contents

Points to be Observed in Supervising Brick Masonry Constructions

The following points should be observed in the construction of brick masonry

- Use bricks of good quality with uniform color, well burnt, with exact shape and size.

- Before using the bricks in masonry, they should be soaked in water for 2 hours so that bricks do not absorb water from the mortar.

- Bricks should be laid with the frog pointing upward.

- Construction of the brick walls should start from the end or corner.

- Brick courses should be perfectly horizontal.

- The verticality of the wall should be ensured by frequently checking with the plumb-bob.

- The mortar used should be as per specification.

- Whenever work is stopped brick masonry should be left with the toothed end.

- The use of brickbats should be avoided.

- Walls should be raised uniformly. In no case difference between adjoining walls is more than 1 m. In a day no wall should be raised by more than 1.5 m.

- To get the proper key for plastering or pointing, the face joints should be raised to a depth of 12 to 20 mm, when the mortar is green. If plastering or pointing is not to be provided, face joints should be stuck flush and finished neatly.

- Holdfasts for doors and windows should be embedded in brick masonry with cement mortar or concrete, at the time of constructing the wall itself.

- Brick masonry should be regularly cured for 2 weeks

- For carrying out brickwork at higher levels, only a single scaffolding should be used.

Advantages and Disadvantages of Brick Masonry Over Stone Masonry

Advantages:

- Since the shape and size of bricks are uniforms, they do not need skilled labor for the construction

- Bricks are light in weight and hence handling them is easy.

- Bricks are easily available around cities and their transportation cost is less because their weight is less. Stones are to be brought from quarries that are located in only a few places.

- It is possible to use all types of mortar in brick masonry. For unimportant buildings, even mud mortar can be used.

- Thinner walls can be constructed with bricks but it is not so with stones.

- It is easy to form openings for doors and windows.

- A dead load of brick masonry is less.

- In brick masonry mortar joints are thin and hence construction cost is reduced considerably.

- Brick masonry has better fire and weather resistance compared to stone masonry.

Disadvantages:

- The strength of brick masonry is less than that of stone masonry

- The durability of brick masonry is less.

- Brick masonry needs plastering and plastered surface needs color washing. Stonemasonry doesn’t need them and hence maintenance cost is more than brick masonry.

- Brick masonry absorbs water and there is the possibility of dampness. There is no such problem in stone masonry.

- More architectural effects can be given in stone masonry compared to brick masonry.

- Stonemasonry gives a massive appearance and hence monumental buildings are built in stone masonry.

Also Read: Water Supply Design | Water Sources and Storage Tanks

Points to be Considered when Supervising Brick Masonry Constructions

The following points should be considered very carefully when constructing brick masonry:

- Be selective, use good-quality bricks.

- Ensure that brick courses are perfectly horizontal.

- The verticality of the wall should be ensured by frequently checking with the plumb-bob.

- Whenever work is stopped brick masonry should be left with the toothed end.

- The use of brickbats should be avoided.

- Raising walls by more than 1.5 m in one day shall be prevented.

- Raise face joints to a depth of 12 to 20mm to be used as a key for plastering or pointing.

- Brick masonry should be regularly cured for 2 weeks.

- The thickness of mortar joints should not exceed 10 mm horizontally and vertically.

We hope this article helped you learn about Brick Masonry | Advantages and Disadvantages. You may also want to learn Home Furniture | Meaning and Type, Engineer | Definition, and History, Floor, and Decor: Types and Materials, and What is the Function of Buildings?

If you liked this article, please Join WebsiteForEngineers on Telegram, and you can also find us on Pinterest, Twitter, and Facebook.