Corrosion is the breakdown of materials due to chemical reactions. It is usually oxidation with air molecules, often occurring in the presence of water. Corrosion also occurs when an acidic/basic corrosive substance comes into contact with another material.

Steel and Concrete have become the most common materials for artificial structures over the last hundred or so years, with the use of the composite material, Concrete reinforced with steel, becoming one of the most popular methods for civil construction.

The historical reasons for steel-reinforced Concrete’s popularity are not hard to find: its cheapness, high structural strength, mouldability, fire resistance, and supposed imperviousness to the external environment, while requiring little or no maintenance, provide a virtually unbeatable combination.

To harness these properties, both national and international standards have been developed. The standards for Concrete and steel were initially defined principally by compositional limits and strength, which has continued to be the primary quality control.

Until the 1950s, it was assumed that when steel was encased in the alkaline Concrete matrix, neither would suffer from any degradation for the indefinite future.

However, evidence of degradation was noted as early as 1907 (Knudsen, 1907), where it was observed that the addition of chlorides to Concrete could allow sufficient corrosion of the steel to cause cracking of the Concrete.

The implicit assumption by many civil engineers that reinforced Concrete’s virtually infinite durability is valid has proven to be accurate in several cases, with structures reaching their design lives without any evidence of structural degradation. However, it is now evident that in areas with an aggressive atmosphere, the Concrete can be damaged, or the steel can corrode dramatically shorter than the specified design life.

Also Read: What is Civil Engineering? | History and Functions

The current design life was initially set at 120 years for UK highways. Despite all the evidence of highway structures showing significant problems after a short period, the Figure remains extremely optimistic, even though no corrosion design life analysis is required.

This head-in-the-sand approach can be contrasted with the reality illustrated by research (Bamforth, 1994), which shows that the estimated time to corrosion activation of steel reinforcement in modern Concrete with the designated cover can be as low as five and a half years at a 0.4% chloride level.

These research findings are in good accordance with site investigations. A substantial number of structures have been found to have their steel reinforcement sufficiently corroded within 20 years of construction, rendering them structurally unsound.

Even after the publicity surrounding the large number of structures exhibiting acute signs of distress 25 or so years into a designed 120-year life span, there is still a body of engineers who believe that all that is required to achieve any specified design life in a hostile environment is to provide a higher Concrete grade with the same design and maintenance of the structure.

This contention does not align with the facts, meaning that publications like this book will address civil engineering miscalculations of the past and those that may be perpetrated in the future.

The traditional use of cathodic protection is to prevent corrosion of steel objects in the ground or water, which remains its most common application. It is almost universally adopted on ships, oil rigs, and oil and gas pipelines. Over the last 50 years, cathodic protection has evolved from being a black art to a science for these applications.

Over the past 30 or so years, there has been a steady increase in the use of cathodic protection for rehabilitating reinforced Concrete structures exhibiting signs of distress.

The most common damage mechanism is chloride-induced corrosion of the steel reinforcement, which is typically what cathodic protection systems are designed to prevent.

Initially, the cathodic protection techniques for reinforced Concrete followed the practice of ‘traditional’ impressed current systems closely but, particularly over the past decade or so, there have been significant developments that have allowed the protection of Concrete structures to become a legitimate and yet distinctly different part of the cathodic protection mainstream with its protection criteria, anode types, and even power supplies.

The object of this volume is to introduce the current state of the art in the cathodic protection of Concrete and outline other related electrochemical techniques for stopping the corrosion of steel reinforcement.

Some guidelines on what cathodic protection is and how and when to use it are also discussed, so that a practising civil engineer or owner should have an introduction to the murky world of cathodic protection for reinforced Concrete.

Recommended Articles

- How To Calculate The Number Of Blocks In a Wall

- How To Simply Estimate The Quantity of Plastering Materials

- Quantities Of Materials For Concrete: The Simple Calculation You Need To Know

- The Basic Civil Engineering Materials: What You Need To Know

- Everything You Need To Know About Ready-Mix Concrete (RMC)

Also Read: Best Types of Kitchen | All You Need To Know- Right Now

Table of Contents

Electrochemical Corrosion

Electrochemical reactions are widely used by humanity for industrial processes such as anodising or chloride production. They are used directly by most people every day of their lives when using a battery.

A surprising number of engineers vaguely remember an explanation in chemistry classes of how a battery operates. This is commonly reiterated as being about electrolytes with ions swimming about, with anodes and cathodes making an appearance, and then dismissed as not necessary in ‘proper’ civil or mechanical engineering.

Unfortunately for those who do not like electrical circuits, corrosion is also an electrochemical process and is of great economic importance, as those with old cars will testify, and has been estimated to consume 4% of the Gross National Product of, for example, the United States (Bennett et al., 1978). This percentage is likely to be of the same order globally.

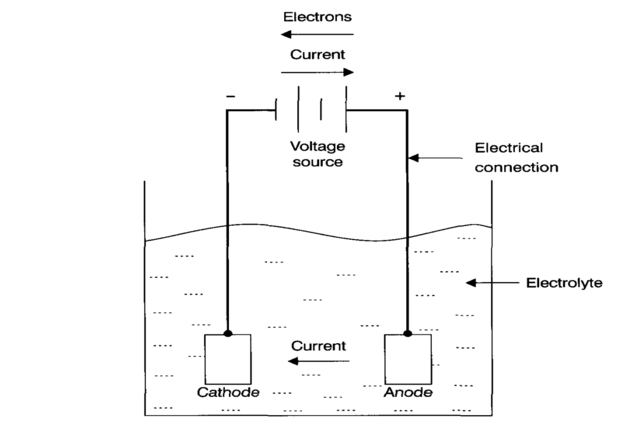

In all low-temperature corrosion reactions and the processes given above, an electrochemical cell is needed for the reactions to occur. This cell comprises an anode and a cathode separated by an electrolytic conductor (electrolyte) with a metallic connection.

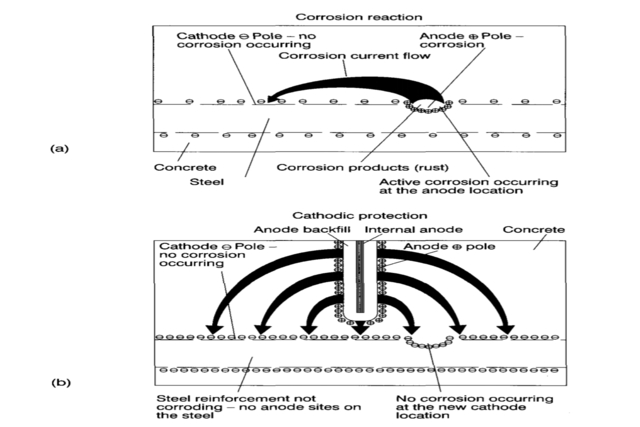

This is shown schematically below. A practical definition of an anode is the area where corrosion occurs, while the cathode is the area where no corrosion occurs.

When a metal, such as steel, is placed in an electrolyte (an aqueous solution that can carry ions, like water with some dissolved rock salt), a corrosion cell can form.

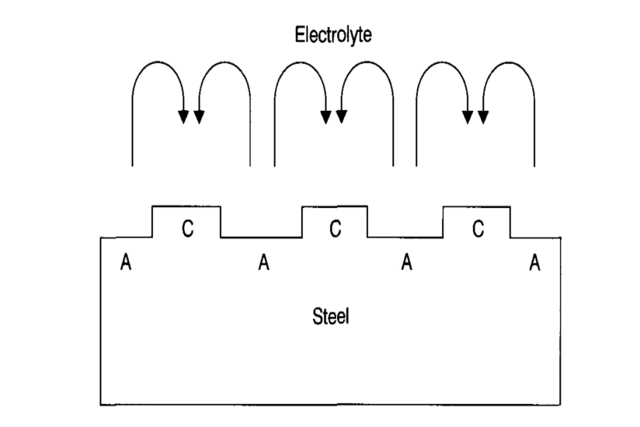

Part of the steel in the electrolyte forms the anode, and part in the same electrolyte forms the cathode. Corrosion, in this case, would occur at all the anode points dispersed around the steel (see Figure below). This gives the appearance of general or uniform corrosion.

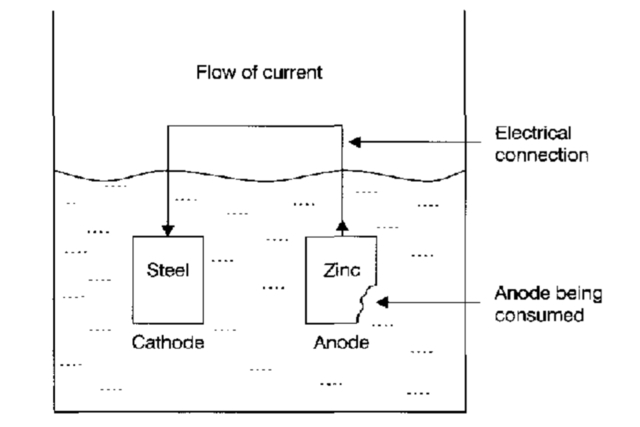

If steel is physically attached (i.e., welded, bolted, or cast) to a piece of zinc and both are placed in an electrolyte, then the zinc will form the anode, while the steel will serve as the cathode.

The result of this will be that all the corrosion reactions will occur on the zinc, which will be consumed, and a balancing reduction reaction (non-corrosion) will appear on the steel, which will not be affected by its immersion in the electrolyte.

This is the basis of cathodic protection. When you cathodically protect steel or any other metal, you change it from acting either as an anode or both an anode and cathode to acting totally as a cathode. This is achieved by the imposition of an external anode, which corrodes preferentially (see the Figure below).

Also Read: Engineer | Definition, and History You Should Know Right Now

Corrosion of Steel

In common with all engineering metals, steel is intrinsically unstable in that it wants to return to its stable state, where it came from as an ore.

The result of this reversion is rust (commonly iron oxide, but it can also be iron sulfide or other compounds), which, while having considerably greater chemical stability, also has considerably reduced mechanical properties, such as strength, compared to the original steel.

With this tendency to corrode, the principal question is not whether steel will rust but how fast it will rust.

The environment and the stability of the oxide layer on the surface usually decide the corrosion rate of steel. The reaction rate is slow if this layer forms a protective skin that remains intact.

If, however, the oxide layer is opened at many places and sloughs off the surface, providing access for more oxygen (which is usually dissolved in water) to the unreacted steel surface. A high corrosion rate can be expected.

Straight carbon and high-yield steels are the most commonly used grades for rebar in normal civil engineering projects. Neither of these types has a particularly protective oxide film, and both rely on the alkalinity of the concrete to stabilise this skin.

There will be a rapid colour change when steel corrodes in a standard atmosphere, i.e., outdoors. This is known as ‘flash’ resting. For example, blast-cleaned steel in a moist environment changes colour when the contractor finishes the blasting operation and opens the paint pots.

This rusting is evidenced by a change in the surface colour from silver to orangey red over all the exposed surfaces. In this case, the corrosion is very rapid because of the presence of ample fuel (oxygen) and the absence of a protective oxide film.

In a saline environment, flash rusting occurs even more quickly, as chloride helps the water conduct an electric current. If the steel were examined visually under a microscope, it would all appear the same colour. In this case, the individual anode and cathode sites are very small, perhaps within a few microns of each other.

In cases where steel is exposed directly to the atmosphere and is at a typical (neutral) pH, with a reasonable supply of oxygen, widespread and uniform corrosion will occur.

This is typically observed when extensive steel sections rust and can be seen on any uncovered steel article, particularly on beaches and other areas with a corrosive atmosphere. An example is given in the Figure above.

When oxygen access to the steel is reduced, which becomes the corrosion-limiting step, i.e., when sufficient aggressive ions are present at the steel interface, allowing the corrosion reaction to occur very quickly, other forms of corrosion may occur.

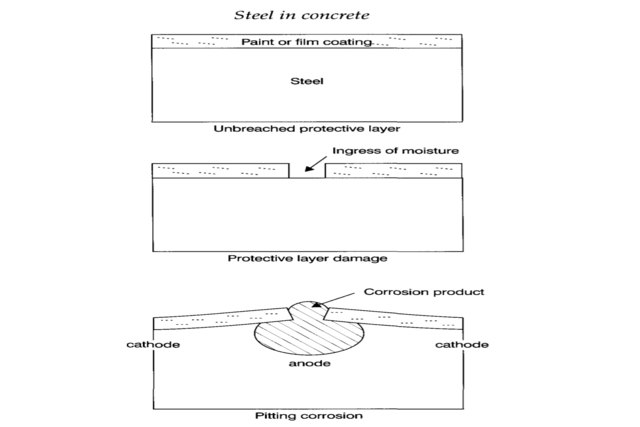

The most common is pitting corrosion. This, for example, occurs when a surface coating on the steel is breached, allowing oxygen and moisture to access a relatively small area. In older cars, these are commonly seen as rust spots. This situation is shown schematically in the Figure below.

Steel in Concrete

Concrete typically provides embedded steel with a high degree of protection against corrosion. One reason for this is that cement, a constituent of Concrete, is highly alkaline.

This means that the Concrete surrounding the steel provides an alkaline environment for the steel. This stabilises the oxide or hydroxide film, thus reducing the oxidation rate (corrosion rate) of the steel.

This state, with a very low corrosion rate, is termed passivation. Another reason Concrete protects embedded steel is that it acts as a barrier against outside elements that are aggressive to the steel.

The chloride ion is the most common agent for the depassivation of steel in Concrete.

The traditional wisdom was that Concrete with a low water-cement ratio, well cured, would have a sufficiently low permeability to prevent significant penetration of corrosion-inducing factors, such as oxygen, chloride ions, carbon dioxide, and water. Unfortunately, this is not the proper position.

Some of this can be explained by the fact that Concrete is inherently porous, regardless of its composition. If a concentration gradient exists, then at some point, a sufficient quantity of aggressive ions will be passed through the Concrete to initiate corrosion.

The crux is at ‘some time’ as this might be sufficiently long to achieve the design life, or it might not. Another reason is probably that cracks exist on all full-scale structures, providing preferential pathways for corrosion-inducing factors.

Fortunately, in most steel-reinforced Concrete structures, corrosion does not occur during the design life. However, this is a situation that arises more by luck than judgment.

With Concrete of a suitable quality, corrosion of steel can be prevented for a specific period, provided that the structure or element is correctly designed for the intended environmental exposure.

In severe exposure, such as bridge decks exposed to de-icing salts or pilings in seawater, the permeability of Concrete conforming to specific standards has been measured, and the time required for the onset of corrosion has been calculated using this data, as shown in the Table below.

| Concrete | Minimum cover (mm) | With a chloride concentration of 0.4% | With a chloride concentration of 1% |

| Old pre-cast standard | 38 | 23.7 | 53.8 |

| BS 8110 (general) | 50 | 5.5 | 12.4 |

| BS 5400 (bridges) | 65 | 9.2 | 20.9 |

| BS 6349 (maritime) | 75 | 12.3 | 27.9 |

As can be seen, a corrosion initiation period of only five and a half years is possible when using modern concrete in compliance with the current standard in a particular environment.

Where the Concrete quality and cover of a new structure are insufficient to provide the required design life, several measures may be employed, such as the use of corrosion inhibitors, coatings on the steel, coatings on the Concrete, or cathodic protection.

The correct choice should be determined by evaluating all options for their cost-effectiveness, reliability, and effectiveness over the design life of the structure.

If the structure is not corrosion-resistantly designed for the anticipated environment, or if the environment and other factors were not as anticipated or changed during the structure’s life, there may be problems.

Instances of distress due to corrosion can be found in almost all applications of modern reinforced or prestressed Concrete; buildings, silos, beams, bridge decks, piles, other supports, tanks, and pipes are some common examples.

Typically, the first indication of distress is the brown staining of the Concrete surface nearest to the corroding embedded steel. This staining is caused by the permeation of iron ions through microcracks in the Concrete to the surface and is often accompanied by the macrocracking of the Concrete shortly afterwards.

The cracking occurs because certain steel corrosion products, such as iron oxides, have a substantially greater volume than the metallic element (iron) from which it was formed. The forces generated by this expansive process exceed the tensile strength of the Concrete, resulting in cracking.

Steel corrosion not only causes structural distress or disfigurement due to staining, cracking, and spalling of the Concrete, but also reduces the compressive strength of the structure (due to the damaged Concrete), and more critically, it can often cause structural failure due to the reduced cross-section and hence reduced tensile capacity of the steel.

This reduced tensile capacity is usually only significant in localised areas and is more structurally critical with prestressing steel tendons than reinforcing bars. This is because the load cannot be easily redistributed in a pre-or post-tensioned structure, unlike cast-in-situ structures.

As an example of the extreme damage which can occur with steel in cracked and stained Concrete, it is common to find that 60 or 70% of the cross-section has corroded through.

All Concrete corrosion engineers have their apocryphal stories describing structures where there has been a 100% section loss of the steel reinforcement. In certain circumstances, this can be seen at many points.

Mechanisms

When reinforcement steel in Concrete corrodes, the process is similar to taking power from an ordinary battery. When steel corrodes in a battery, a metal dissolves, producing a small current between the positive and negative poles.

For steel reinforcement corroding in the Concrete, one tiny area is the anode (positive pole), and another, much more extensive area is the cathode (negative pole).

The corrosion current flows out of the steel at the anode, the part that is corroding, through the Concrete and into another part of the steel where no corrosion is occurring, i.e., the cathode. This flow is referred to as a corrosion circuit. Steel is dissolved at the anode and eventually forms iron oxide at this location.

The electrical connection between + and • can be disconnected from a battery. The circuit is then broken, resulting in the current being stopped, and thus the dissolution of the metal is halted.

For steel reinforcement in Concrete, the ionic flow running through the Concrete and the attachment between the steel cannot be disconnected, as the corrosion circuit is buried in the structure.

Instead, it is possible by using an ‘artificial’ anode to add a new and higher current to the original corrosion circuit, which runs in the opposite direction of the corrosion current.

This makes all the previous +poles (anodes) into current receivers. Thus, all the steel reinforcement is made into a negative pole, i.e., cathodic, hence the name ‘cathodic protection.’

In electrochemical corrosion, a flow of electrical current and one or more chemical processes are required for metal loss.

The flow of electrical current can be caused by ‘stray’ electrical sources, such as from a train traction system or from significant differences in potential between parts of the structure caused by factors such as differential aeration from the movement of seawater (the mechanism for this is still uncertain, but it could be that vast cathode area are built up in the tidal zone because of oxygen charging.

Electrochemical corrosion by these electrical current sources is rare but can be serious when it occurs. Often, this process can contribute to corrosion when other aggressive factors arise.

The passivation of the steel by the alkalinity would likely allow a certain amount of current discharge from the steel without metal loss. The critical factor in this is the resupply of the alkalinity relative to the current drain.

Instances of stray current corrosion occurring have been recorded. An example was a jetty where the piles were being cathodically protected, and the reinforced Concrete deck was being used as the system’s negative.

Unfortunately, several of the piles were electrically discontinuous, and corrosion occurred at a secondary anode point formed on these piles as the current attempted to flow back to the system negatively.

The vast majority of the potential gradients found between different areas of the steel in Concrete are caused by the existence of physical differences or non-uniformities on the surface of the steel reinforcement (different steels, welds, active sites on the steel surface, oxygen availability, and chloride contamination).

These potential gradients can allow significant electrical current to flow and, under certain circumstances, such as with aggressive ions in the Concrete, cause corrosion of the reinforcement.

Even though the potential for electrochemical corrosion may exist due to the non-uniformity of the steel in the Concrete.

This corrosion is usually prevented, even at nominally (i.e., more harmful in potential than the cathodic area) anodic sites, by the passivated film that forms on the steel surface in the presence of moisture, oxygen, and water-soluble alkaline products formed during the hydration of the cement.

There are two mechanisms by which the highly alkaline environment and accompanying passivation effect may be destroyed, namely:

- The reduction of alkalinity is achieved by the leaching of alkaline substances by water or partial neutralisation when reacting with carbon dioxide or other acidic materials.

- Electrochemical action involves aggressive ions acting as catalysts (typically chloride) in the presence of oxygen.

Reduction of alkalinity by reaction with carbon dioxide, as present either in the air or dissolved in water, involves neutralising reactions with the sodium and potassium hydroxides and, subsequently, the calcium system, which is part of the Concrete matrix.

This process—called carbonation—although progressing increasingly slowly, may in time penetrate the Concrete to a depth of 25mm or so (depending upon the quality of the Concrete and other factors) and thereby neutralise the protective alkalinity normally afforded to steel reinforcement buried to a lesser depth than this.

This damage is particularly apparent in low-grade concrete structures where the builders were economical with the cement and liberal with the water.

The second mechanism by which the passivity of the steel in the concrete can be disrupted is through electrochemical action involving chloride ions and oxygen.

As previously mentioned, this is by far the most critical degradation mechanism for reinforced concrete structures, and the most significant factors influencing this reaction are discussed below.

Also Read: The Contractor | Types, Responsibilities, and Conditions You Need To Know

Alkalinity and chloride concentrations:

The high alkalinity of the chemical environment usually present in Concrete protects the embedded steel because of the formation of a protective film, which could be either an oxide or a hydroxide, or even something in the middle, depending on which research paper you read.

The integrity and protective quality of this film depend on the environment’s alkalinity (pH). The bulk alkalinity of the concrete depends on the water-soluble alkaline products.

The principal soluble product is calcium hydroxide, and the initial alkalinity of the Concrete is at least that of saturated lime water (pH of about 12.4, depending upon the temperature).

Additionally, the cement contains relatively small amounts of sodium and potassium oxides, which can further increase the alkalinity of the Concrete or paste extracts. pH values of 13.2 and higher have been reported.

The higher the alkalinity, the greater the protective quality of this film. Steel in Concrete becomes potentially more susceptible to corrosion as the alkalinity is reduced.

Additionally, steel in Concrete becomes more susceptible to corrosion with increasing quantities of soluble chlorides present at the iron-cement paste interface. Chloride ions appear to be a specific destroyer of the protective oxide film.

Chloride can be present in ‘as-manufactured’ Concrete as a set accelerator (calcium chloride) or through contamination of the mix. However, more commonly, the chloride has come from an external source, such as de-icing salts or marine environments.

In these latter cases, the salt diffuses through the Concrete cover to the steel. It is worth noting that in practice, the rate of diffusion in an exposed marine or de-icing salt environment can be significantly higher than might be estimated when using cement or Concrete diffusion tests. This is because the transport process utilises convection and capillary movements in real structures.

Although chloride ions are soluble in the cement paste, most of the chlorides will not be in solution in the liquid within the paste. This is because the chlorides react with hydrated tricalcium sulfoaluminate, a constituent of the past, to produce a corresponding tricalcium chloroaluminate compound.

It has been shown that as much as 75–90% of the chloride in the cement paste exists in the chloroaluminate compound and is thus ‘bound’ and unable to interact with the steel reinforcement.

This concentration depends upon the total amount of chloride present, the tricalcium aluminate (C3A) content, and the degree of hydration of the cement.

Although only a fraction of the chloride is in solution, it is in a dynamic equilibrium. Thus, the chloroaluminate compound present would allow resupply if the free chloride were leached out.

The relationship between the onset of steel corrosion and the alkalinity and chloride concentration in the environment has not been fully defined for in-situ Concrete.

It is unlikely to be so without a definition of the aggregate and cement types and quantities. It has been suggested, and it seems reasonable, that a threshold concentration of chloride ions must be exceeded in an oxygen-rich environment before a significant level of steel reinforcement corrosion occurs. Some of the defined values for this level are given in the Table below.

| Authority | % of Cl by weight of cement |

| Wegler | 0.40 |

| BS CP11 1979 | 0.36 |

| Clear | 0.20 |

| Knofel | 0.20 |

| ACI Committee 201 | 0.20 – 0.10 |

| Vassie | 0.10 |

As can be seen, there is an extensive range of defined critical values. Part of the reason is that a scientist would probably define the onset of corrosion as the point at which sufficient chloride is present at the rebar to catalyse the corrosion reaction.

In contrast, if a site investigation reveals a low corrosion rate in commercial structures, then a visual inspection would suggest that no corrosion is occurring.

This observation would allow the erroneous conclusion that the threshold had not been reached. Whatever the critical concentration level, it appears certain that both the structural environment and the Concrete significantly affect the essential concentration of chlorides required to initiate corrosion properly.

A hydroxide-to-chloride concentration ratio can more accurately describe these critical values. This has been given, among others, by Hausmann (1967) as:

It is sometimes found that reinforced Concrete with uniformly high levels of chloride contamination (often over 3%) does not have significant corrosion of the rebar.

This typically occurs when there are constant environmental conditions surrounding the Concrete, such as internal walls of a building or structures buried beneath a saline water table.

Conversely, in areas where there are cyclical environmental conditions, such as where Concrete is exposed to strong tidal flows of aerated salt water or where there are daily weather conditions, e.g., where there is direct sunlight in the day and high humidity and low temperatures in the night, there can be significant damage at low chloride concentrations.

Various ideas have been proposed on what chloride is doing to cause this depassivation, but there seems to be agreement that, in localised areas, the passive film is broken down, resulting in pitting.

In the pits, an acidic environment exists, and when Concrete is stripped from the corrosion sites on the steel, green-black and yellow-black compounds can often be observed.

These are probably intermediate complexes that contain chloride and allow a lower activation energy for oxidation. In the corrosion process, chloride is not held as a final product and can be thought of as acting as a catalyst.

Any increase in chloride ion concentration beyond the initiation level will likely increase the corrosion rate. At some point, other factors will become the rate-limiting step. This rate-limiting step in reinforced Concrete is commonly the availability of sufficient oxygen.

Oxygen level:

A crucial factor in the corrosion of steel in Concrete is the presence of oxygen at the steel-cement paste interface. Oxygen is required in addition to chloride or reduced alkalinity.

If oxygen is not present, there should be no oxidation. For example, seawater has been successfully used as mixing water for reinforced Concrete, where the Concrete is continually and completely submerged in seawater at the seabed.

This is because of the maintenance of high alkalinity due to the sodium chloride (this boosts the Concrete’s alkalinity due to sodium ions’ higher solubility in the cement paste), low oxygen content in the seawater at the seabed, and the very slow diffusion rate of oxygen through the water-saturated paste.

There would initially be a high corrosion rate when the critical chloride ratio was achieved. This would deplete the available oxygen, and the corrosion rate would dramatically reduce, despite an increasing chloride concentration.

This slowing of the corrosion rate is assisted by a reduction in the oxygen solubility of water at extremely high chloride saturation levels, which further reduces oxygen availability.

In most cases, when the structure is submerged, the oxygen diffusion process is the rate-controlling step in the speed of the corrosion.

The level of oxygen supply or resupply also affects the corrosion products formed. A black product (magnetite) is formed in low oxygen availability, and a red-brown material (haematite) is favoured in high oxygen availability.

The pore sizes of these oxides differ, with the red product forming a more open structure featuring larger pores. The formation of haematite imparts a higher bursting pressure on the concrete because of its greater volume.

It allows for a quicker reaction due to its greater porosity relative to magnetite. For these reasons, the presence of haematite rather than magnetite tends to indicate general corrosion rather than pitting and vice versa.

Cement type:

The Concrete composition significantly affects corrosion damage at varying chloride concentrations. One example is that hardened Concrete appears to have a lower chloride tolerance level than concrete contaminated during the mixing process.

This is practically evident in pre-cast units, which tend to corrode less than might be anticipated, even when heavily dosed with a calcium chloride set accelerator (this is probably at least partially explainable due to their higher quality relative to cast-in-situ reinforced concrete of the same vintage and the absence of any potential differences caused by concentration gradients).

Although the cement composition and type can affect corrosion, this effect is relatively small compared to the quality of the concrete, the cover over the steel, and the consolidation of the Concrete.

Using cement with a high C3A content will tend to bind more chlorides, thereby reducing the amount of chloride available to disrupt the oxide film on the steel reinforcement.

Additionally, a cement with a high alkali content would appear to offer advantages due to its higher inherent alkalinity. In general, it is observed that cement high in C3A affords better corrosion protection to reinforcing steel. Still, it is thought that other factors, such as fineness and sulfate content, may have at least as significant an effect.

One study by Tuutti (1982) found that Portland cement had a higher initiation level than slag cement. Still, a lower diffusion resistance is postulated, suggesting that under certain exposure conditions, a specific mix design with Portland cement would be superior. In contrast, under other conditions, the reverse would be true, and slag cement would be exceptional.

It was noted that sulfate-resisting cement was always less effective than Portland cement.

Aggregate type and other additives:

In general, the higher the strength of the aggregate, the more likely it is to be resistant to the passage of ions. But this is not always so.

For example, granite aggregate has been used for several significant projects due to its high strength; however, Concrete made with this material has been found to provide relatively poor diffusion resistance results. This is likely due to microcracks in the aggregate.

Likely, a substantial amount of the diffusion in Concrete proceeds along the interface between the aggregate and the cement paste. This region may prove to be more critical than the bulk diffusion resistance of the aggregate. Specific aggregates have a smoother profile than others, affecting the apparent diffusion path.

Adding additives, such as microsilica, to the Concrete is beneficial as it increases the diffusion path by blocking the pores in the Concrete.

The primary concern with this and other additives is the additional care required when casting on the construction site, as well as the assumption that the Concrete will transform into an impermeable covering with additive X. This is not a safe assumption, as the Concrete will still retain some degree of porosity.

We hope this article helped you learn about Corrosion in Reinforced Concrete: Causes, Prevention, and More. You may also want to know about Construction Estimating: Types, Opportunities, The Estimator, and More, 2022 Top 10: Our Most Popular Posts of the Year, Engineering Universities in Tanzania You Should Know, and Cement | Types, Composition, and All You Need to Know.

Join the conversation by replying on Bluesky.

That’s all.

If you liked this article, please join Website For Engineers on Twitter, Facebook, TrueSocial, Pinterest, BlueSky, and in our WhatsApp channels.